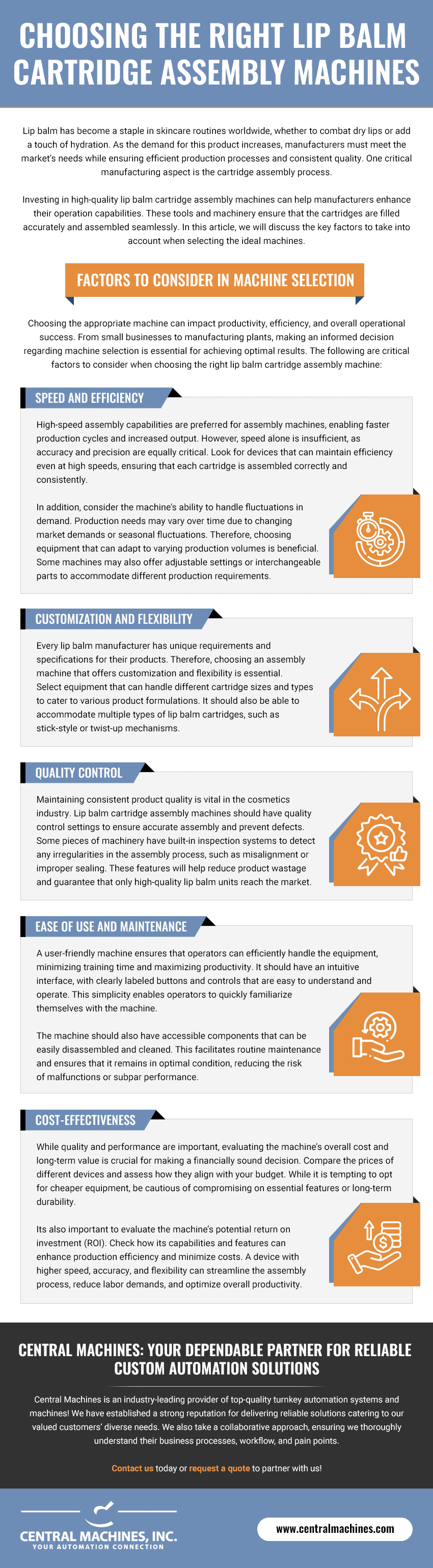

Choosing the Right Lip Balm Cartridge Assembly Machines

Lip balm has become a staple in skincare routines worldwide, whether to combat dry lips or add a touch of hydration. As the demand for this product increases, manufacturers must meet the market’s needs while ensuring efficient production processes and consistent quality. One critical manufacturing aspect is the cartridge assembly process.

Investing in high-quality lip balm cartridge assembly machines can help manufacturers enhance their operation capabilities. These tools and machinery ensure that the cartridges are filled accurately and assembled seamlessly. In this article, we will discuss the key factors to take into account when selecting the ideal machines.

Factors To Consider in Machine Selection

Choosing the appropriate machine can impact productivity, efficiency, and overall operational success. From small businesses to manufacturing plants, making an informed decision regarding machine selection is essential for achieving optimal results. The following are critical factors to consider when choosing the right lip balm cartridge assembly machine:

Speed and Efficiency

High-speed assembly capabilities are preferred for assembly machines, enabling faster production cycles and increased output. However, speed alone is insufficient, as accuracy and precision are equally critical. Look for devices that can maintain efficiency even at high speeds, ensuring that each cartridge is assembled correctly and consistently.

In addition, consider the machine’s ability to handle fluctuations in demand. Production needs may vary over time due to changing market demands or seasonal fluctuations. Therefore, choosing equipment that can adapt to varying production volumes is beneficial. Some machines may also offer adjustable settings or interchangeable parts to accommodate different production requirements.

Customization and Flexibility

Every lip balm manufacturer has unique requirements and specifications for their products. Therefore, choosing an assembly machine that offers customization and flexibility is essential. Select equipment that can handle different cartridge sizes and types to cater to various product formulations. It should also be able to accommodate multiple types of lip balm cartridges, such as stick-style or twist-up mechanisms.

Quality Control

Maintaining consistent product quality is vital in the cosmetics industry. Lip balm cartridge assembly machines should have quality control settings to ensure accurate assembly and prevent defects. Some pieces of machinery have built-in inspection systems to detect any irregularities in the assembly process, such as misalignment or improper sealing. These features will help reduce product wastage and guarantee that only high-quality lip balm units reach the market.

Ease of Use and Maintenance

A user-friendly machine ensures that operators can efficiently handle the equipment, minimizing training time and maximizing productivity. It should have an intuitive interface, with clearly labeled buttons and controls that are easy to understand and operate. This simplicity enables operators to quickly familiarize themselves with the machine.

The machine should also have accessible components that can be easily disassembled and cleaned. This facilitates routine maintenance and ensures that it remains in optimal condition, reducing the risk of malfunctions or subpar performance.

Cost-Effectiveness

While quality and performance are important, evaluating the machine’s overall cost and long-term value is crucial for making a financially sound decision. Compare the prices of different devices and assess how they align with your budget. While it is tempting to opt for cheaper equipment, be cautious of compromising on essential features or long-term durability.

Its also important to evaluate the machine’s potential return on investment (ROI). Check how its capabilities and features can enhance production efficiency and minimize costs. A device with higher speed, accuracy, and flexibility can streamline the assembly process, reduce labor demands, and optimize overall productivity.

Central Machines: Your Dependable Partner for Reliable Custom Automation Solutions

Central Machines is an industry-leading provider of top-quality turnkey automation systems and machines! We have established a strong reputation for delivering reliable solutions catering to our valued customers’ diverse needs. We also take a collaborative approach, ensuring we thoroughly understand their business processes, workflow, and pain points.

Contact us today or request a quote to partner with us!