Custom automation equipment is specialized machinery and systems tailored to automatically perform specific functions or needs of a particular application or process. Unlike off-the-shelf solutions, it is custom-designed to optimize efficiency, enhance productivity, and address unique requirements.

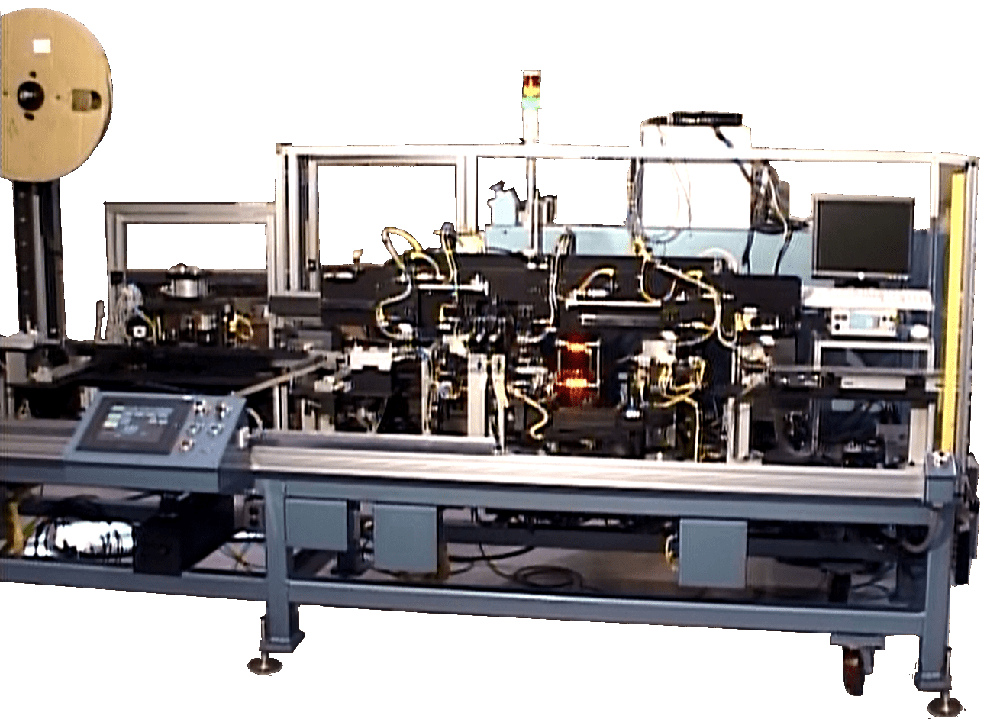

Central Machines, Inc. is your trusted partner in designing and building custom automation, testing, and inspection assembly equipment. Our comprehensive range of services offers a turnkey operation, covering every aspect of your project from start to finish. Moreover, our expertise and dedication to excellence ensure you receive top-notch solutions tailored to your unique requirements.

Design-Build Process of Custom Automation Equipment

The process of developing and building custom equipment for automated manufacturing processes includes the following key stages:

STEP 1: CONCEPTUALIZATION AND REQUIREMENTS GATHERING

The design-build process begins with the conceptualization phase, where the automation needs are identified. This involves thoroughly understanding the manufacturing processes, pain points, and desired outcomes. Then, collaborating with the client, the automation team gathers detailed requirements to ensure the solution addresses all critical aspects.

STEP 2: DESIGN AND ENGINEERING

In this step, the initial design concept takes shape, considering factors such as equipment layout, mechanical and electrical components, and software integration. Then, detailed engineering and prototyping are conducted to refine the design and validate its feasibility.

STEP 3: MANUFACTURING AND FABRICATION

This step involves selecting the appropriate materials, sourcing components, and fabricating the various parts of the automation equipment. Additionally, skilled technicians and engineers work together to assemble and integrate the components into a functional system.

STEP 6: TRAINING AND SUPPORT

Operator training and comprehensive documentation are provided to the client’s team in this step. This ensures that the operators are proficient in using and maintaining the custom automation equipment. Additionally, the design-build partner offers post-installation support and maintenance services to address any issues.

Key Benefits of Custom Automation Equipment

Custom automation equipment offers numerous advantages for businesses across various industries. Here are some key benefits that you can expect:

INCREASES EFFICIENCY AND PRODUCTIVITY

By eliminating manual processes and reducing human intervention, businesses can achieve higher output levels while maintaining consistent quality. Automation also allows for faster production cycles, enabling companies to meet customer demands more effectively and stay ahead in competitive markets.

IMPROVES ACCURACY AND QUALITY CONTROL

Automation minimizes the risk of human error and enhances accuracy in production processes. Thus, automated equipment operates with precision, ensuring consistent and precise outcomes. This leads to improved quality control, reduced defects, and higher customer satisfaction.

ENHANCES SAFETY AND RISK MITIGATION

Companies can promote employee well-being and better comply with industry regulations by creating a safer work environment. In addition, businesses can significantly reduce workplace accidents and injuries by automating potentially dangerous processes.

PROMOTES SCALABILITY AND FLEXIBILITY

As businesses grow or introduce new product lines, automation equipment can be easily modified or expanded to accommodate increased or adjusted demand. This scalability ensures long-term cost savings and provides the agility required to stay competitive in dynamic markets.

ENSURES COST SAVINGS AND RETURN ON INVESTMENT

Automation reduces labor costs associated with repetitive tasks, minimizes material waste, and optimizes energy consumption. By improving operational efficiency and reducing manual labor requirements, businesses can achieve a higher return on investment over time.

OPTIMIZES DATA COLLECTION AND ANALYSIS

Custom automation allows businesses to gather real-time data on production processes, performance metrics, and equipment health. By analyzing this data, companies can identify bottlenecks, optimize production workflows, and make data-driven decisions to improve operational efficiency and performance.

BOOSTS COMPETITIVE ADVANTAGE

By leveraging automation technologies, businesses can enhance their capabilities, deliver products faster, and maintain a high level of quality. In addition, this strengthens customer relationships and positions companies as industry leaders, attracting new customers and opportunities.

Industries and Applications

Custom automation equipment finds applications in various industries, providing tailored solutions to meet specific operational needs. These include the following:

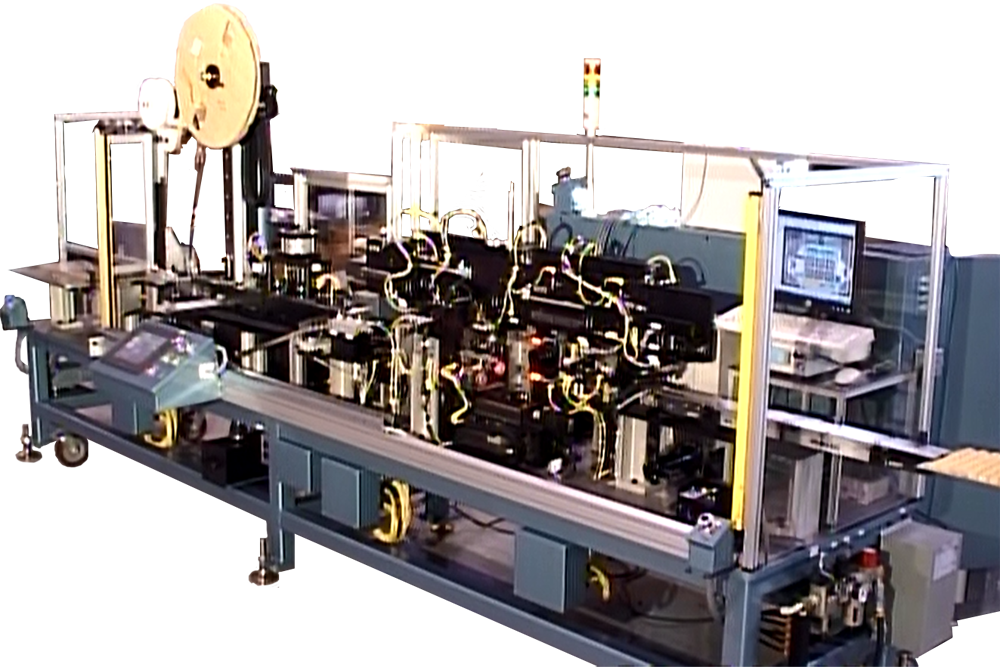

MANUFACTURING AND ASSEMBLY

Custom automation equipment plays a vital role in manufacturing and assembly processes across the automotive, electronics, consumer goods, and pharmaceutical industries. It can automate tasks like component assembly, product testing, packaging, and quality control.

FOOD AND BEVERAGE

Automated systems can handle sorting, weighing, filling, sealing, and labeling tasks in the food and beverage sector. These solutions increase production speed, maintain hygiene standards, and reduce the risk of contamination.

PHARMACEUTICALS AND MEDICAL DEVICES

Custom automation equipment — including drug formulation, blister packaging, labeling, and medical device assembly — is crucial in manufacturing. Automation ensures accurate dosage, minimizes cross-contamination, and enhances product traceability, meeting the stringent standards of these industries.

ELECTRONICS AND SEMICONDUCTOR

Custom automation equipment is utilized for tasks such as printed circuit board assembly, component testing, chip handling, and packaging. It also enables seamless integration with other manufacturing systems, optimizing the production line.

AUTOMOTIVE AND AEROSPACE

Automated systems are used in automotive and aerospace assembly lines for welding, painting, parts handling, and final assembly tasks. It also allows efficient handling of complex components and precise positioning, meeting the stringent requirements of these industries.

LOGISTICS AND WAREHOUSING

Custom automation equipment streamlines processes such as material handling, sorting, inventory management, and order fulfillment in logistics and warehousing. Automated systems can efficiently move goods, track inventory levels, and optimize storage space utilization.

ENERGY AND ENVIRONMENT

The energy and environmental sectors benefit from custom automation equipment for power generation, waste management, and renewable energy production tasks. Custom automation solutions enable precise control and monitoring of energy systems, ensuring optimal performance and resource utilization.

Why Choose Central Machines, Inc.

When it comes to custom automation equipment, choosing the right partner is crucial to ensure the success of your projects. Here are some compelling reasons Central Machines, Inc. stands out as the preferred choice for businesses seeking top-quality automation solutions:

EXTENSIVE EXPERTISE AND EXPERIENCE

With years of industry experience, we have developed a deep understanding of the intricacies of designing and building custom automation equipment. As a result, we have successfully executed numerous projects across various industries, earning a reputation for excellence and reliability.

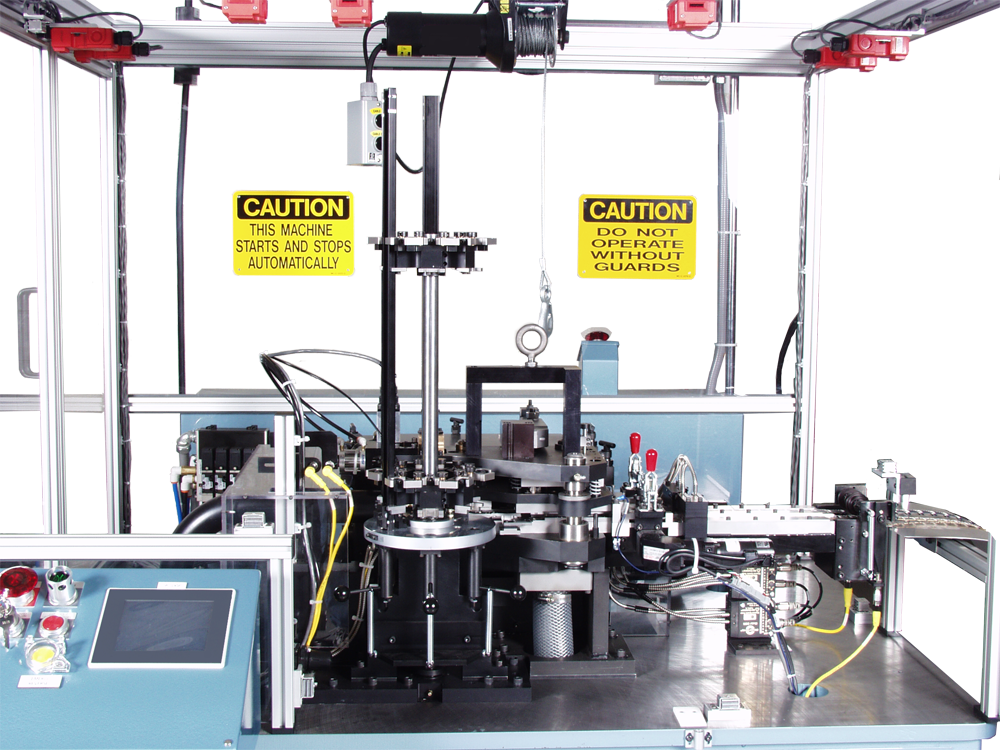

TURNKEY SOLUTIONS

At Central Machines, Inc., we provide turnkey solutions to streamline the implementation process of custom automation equipment. We handle every aspect of the process from initial engineering design to custom machine shop fabrication, manufacturing, assembly, wiring, programming, installation, training, and support service.

CUSTOMIZATION OPTIONS

Whether you need continuous motion or indexing, rotary or inline equipment, we can tailor our solutions to align perfectly with your assembly application. In addition, you can select from our existing standard chassis platforms or opt for a fully custom design for optimal performance.

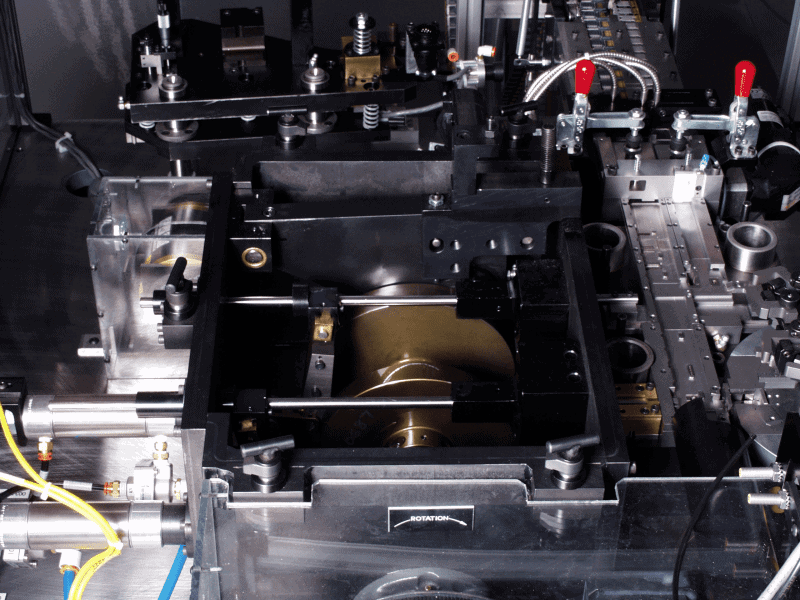

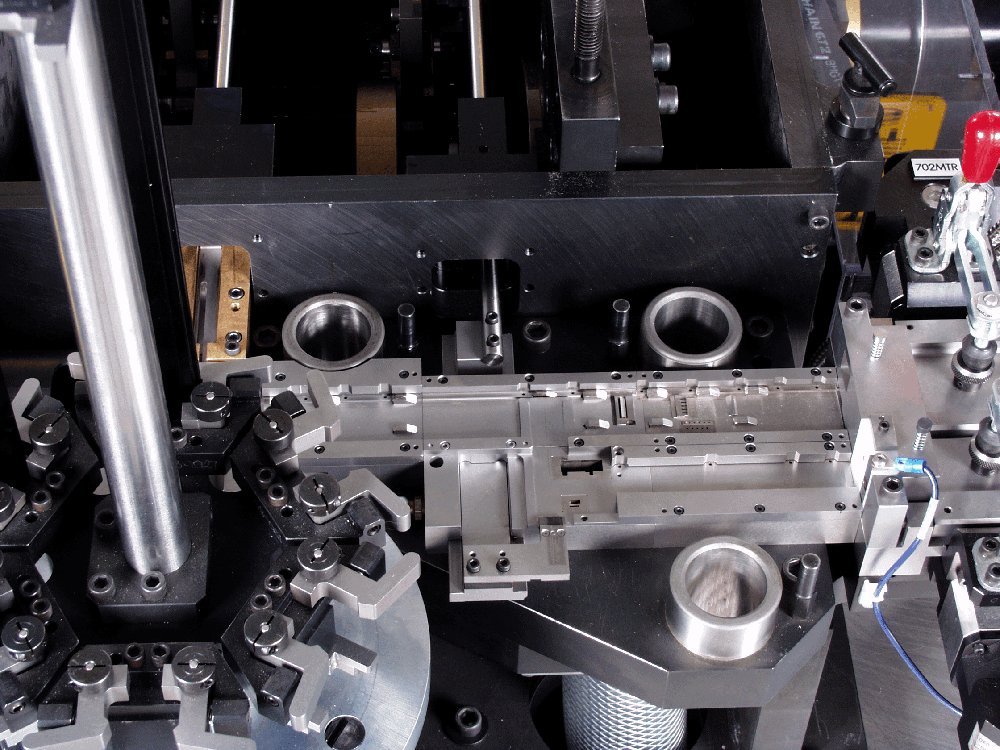

ADVANCED TECHNOLOGY AND IN-HOUSE MANUFACTURING

Our in-house machine shop is equipped with conventional and CNC equipment, allowing us to control the entire production process. In addition, we utilize CAD/CAM integration, CNC machines, wire EDM machines, and AutoDesk Inventor design software to ensure precise construction and excellent repeatability.

QUALITY AND RELIABILITY COMMITMENT

We maintain stringent quality control measures throughout the design, fabrication, and assembly process to ensure that our automation equipment meets the highest industry standards. By combining robust construction, mechanical and servo-driven motion, and meticulous attention to detail, we deliver machinery that exhibits exceptional longevity and consistency.