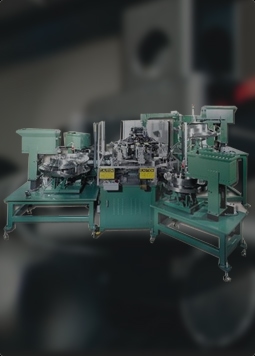

Custom Designed

Automation Equipment

- Full in house turnkey capabilities from design, manufacturing, wiring, assembly, programming, installation, training and service.

- Innovative designs in a broad range of markets served brings a broad range of experience to serve our custom capabilities.

- Customers can choose from CMI standard machine chassis platforms or custom designed to best suite application.

- Design and construction of inline,rotary indexing, continuous motion, power/free, servo drives and robotics.

Equipment by Application

About us

Central Machines, Inc.

Through state-of-the-art prototyping and process development, we provide custom high-speed assembly machines for virtually any industry. We utilize the latest machine vision systems technology to ensure each machine we manufacture meets our clients’ guidelines and specifications.

We specialize in the design and construction of in-line, rotary, indexing, continuous motion, power/free, and contact insertion process equipment.

Automation is a necessity for all types of manufacturers; pharmaceuticals, electronics, electric controls, automotive, plastics and packaging. Wherever there is a need for fast, efficient and repetitive assembly of parts, you will find our equipment. When it comes to custom assembly systems, Lincolnshire, Ill.-based Central Machines Inc. offers some of the most innovative automation systems in the industry. The company specializes in continuous motion.

Proudly manufactured in the US and distributed Globally.

Learn MoreTestimonials

View AllBlog

Automation equipment manufacturers lead industrial innovation and develop cutting-edge technologies that streamline manufacturing processes. They are crucial in advancing modern industry by enhancing precision, productivity, and efficiency, which enables enterprises to remain competitive. As the need for smarter and more efficient manufacturing solutions intensifies, these manufacturers consistently push the boundaries, shaping the future of industrial […]

Learn MoreAutomated equipment manufacturing uses advanced machinery and software to perform production tasks with minimal human intervention. This cutting-edge technology is revolutionizing modern industry by enhancing efficiency, precision, and productivity. As automation advances, it becomes increasingly vital for businesses to stay ahead of trends to maintain a competitive advantage. This article explores the trends and advancements […]

Learn MoreIndustrial automation equipment uses control systems, such as computers and robots, to handle different processes and machinery. The revolution of industrial automation has profoundly impacted manufacturing by enhancing operational efficiency, reducing errors, and increasing production flexibility. This article explores how industrial automation equipment improves operational effectiveness, adapts to various industry needs, and reshapes manufacturing. Roles […]

Learn More