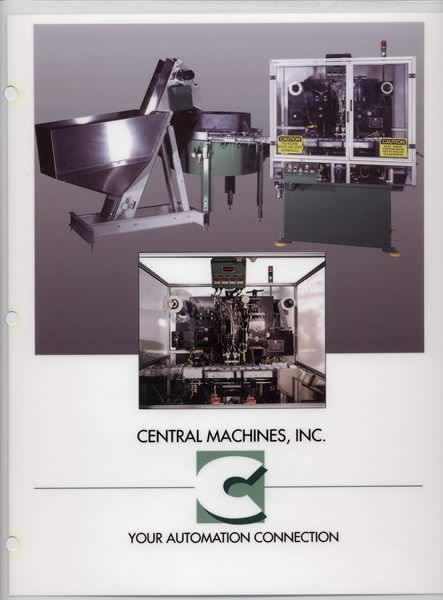

Our clients have the ability to design their own custom automation equipment based on their needs, including traditional punch-and-die equipment, indexing machines, and much more. Our industrial automation equipment is proudly manufactured in the USA and is utilized by many companies around the world.

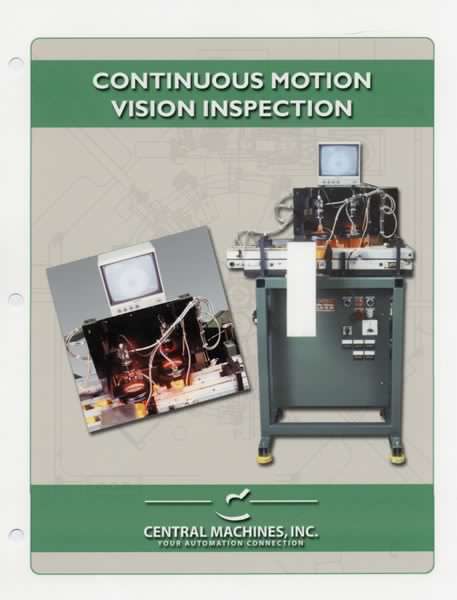

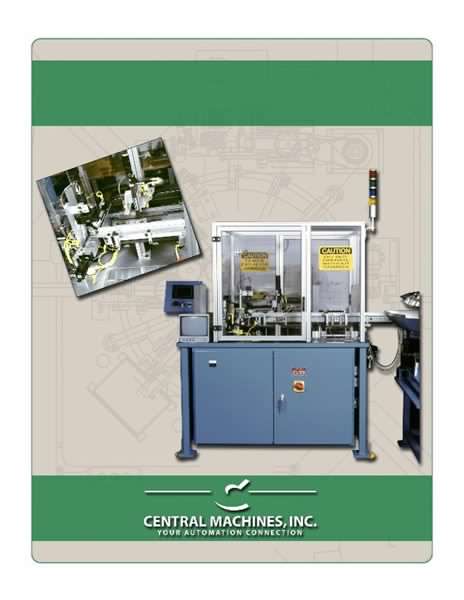

Central Machines, Inc. designs and builds custom automated test equipment, testing, and inspection assembly equipment. We provide turnkey operation from full engineering design, custom machine shop fabrication and manufacturing, assembly, wiring, programming, installation, training, and service. Our designs can be either continuous motion or indexing; rotary or inline, depending on requirements. Customers can choose from either our existing standard chassis platforms or select to have a custom automation equipment design best suited for their assembly application. Our core competencies include the design and build of high-speed indexing dial assemblies, walking beam-type transfer systems, palletized transfer systems, cap closing machines, cap lining machines, and continuous motion assembly machines.

Our industrial automation equipment delivers both longevity and excellent repeatability due to our use of mechanical and servo-driven motion. Complete construction of the machine is done in-house using a CAD/CAM integration of CNC and wire EDM machines, with our engineering AutoDesk Inventor design software. Our machine shop is outfitted with all the conventional and CNC equipment necessary to manufacture all of our equipment in-house.

Our custom automation equipment is user-friendly and easily programmable. The machines feature a color display touch screen panel as the primary interface. Using the touch screen, the equipment can be programmed to run multiple jobs. Operators need only to enter a part number into the touch screen of the machine; this will access its local database to start producing the part.

We performance test, debug, and install all the equipment that we build. Our skilled personnel provide on-site maintenance and servicing support.

From each and every machine, our customers can expect longevity and reliability due to our use of mechanical and servo-driven motions. Our skilled workforce is all under one roof, allowing for complete construction and product accountability within our shop. We use both conventional and state-of-the-art CAD/CAM, CNC, and wire EDM machines to fabricate the components.

- Capabilities

Machine Shop Capabilities Buffing

CNC Machining

Drilling

Milling

Sawing

Stamping

Welding

Wire EDM MachiningCustom Services 24/7 Service

Complete Machine Programing

Custom Build Manufacturing

Functional Testing

Innovative Machine Design

Installation At Your Location

Retooling and Upgrades of our machines and our competitor’s machines

Stand Alone Machines

Training Your Staff

Turnkey Systems

Wiring and Assembly

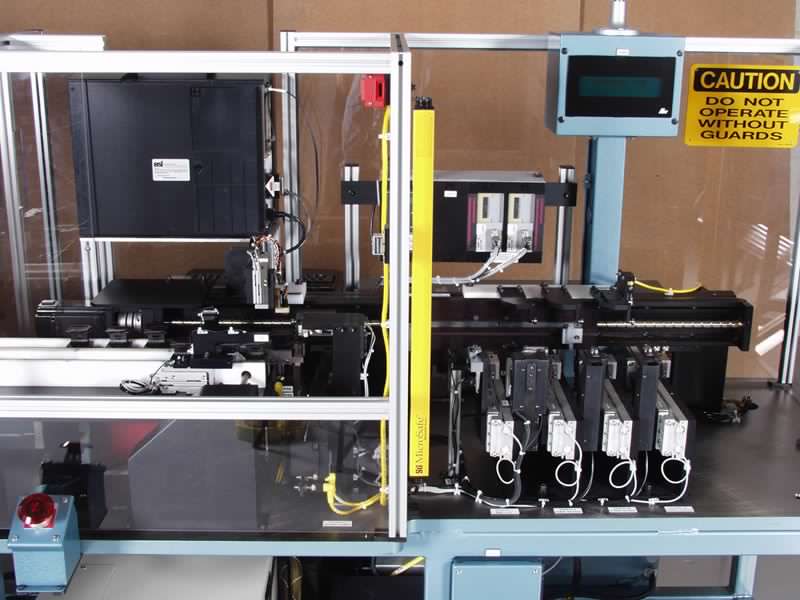

Vision SystemsTolerances Operating Placement: +/- .002

Tooling tolerance: +/- .001Sensor Capability Verify product has no defects

Verify Product was assembled correctly

Verify Product was loaded into the dials

Verify that products with defects are removedCore Competencies Cap Closing Machines w/ max. 550 ppm

Cap Lining Machines w/ max. 1200 ppm

Continuous Motion Assembly Machines w/ max. 1300ppm

High Speed Indexing Assembly Dial w/ Typical min. 25 ppm to max. 150 ppm.

Walking beam-type transfer systems - Types of Transfer Systems

Types of Transfer Systems Continuous motion

Indexing dial

Inline walking beam

Carousel

Over / under

Palletized conveyor systems

Linear servo transfer

Robotics with end of arm toolingIn Feed Systems Power driven conveyors tracks

Regenerative blower tracks

Compressed air tracks

Vibratory inline tracksProduct Transfer to Assembly or Test Processes Direct feed

Cam / servo / pneumatic driven pick and place units

Servo / pneumatic driven gantries

Cam / servo / pneumatic driven shuttles

Product Placement Detection See through fiber optic sensors

Convergent beam sensors

Laser sensors

Probe tooling with sensorsProduct Assembly Types Snap together

Interference fit

Adhesive

Dispensing

Ultra sonic welding

Heat staking

Welding

Spin welding

Induction welding

Conduction welding

Screwing

RivetingProduct Assembly Testing Vision system inspections

Probe tooling with sensors

Laser sensors

Leak testing (pressure or vacuum)

Spark testing (Leak testing)

Hi- Pot electrical high voltage testing

Go / No go tooling gages

LVDT force testing

Automatic ejecting of product to sampling binsProduct Identification Laser engraving

Ink jet printing

Labeling

Pad printing

Pin stampingPre Feeders Elevator hoppers

Vibratory hoppers

Live bottom hoppersFeed Systems Vibratory feeders

Centrifugal feeders

Water fall feeders

Step feeders - Inspection & Testing

Functional Testing and Inspection 24 hour non-stop dry run test

Electrical test on connectors: Hypot test

Multi stage load test

Standard ChecklistProject Completion Internal Check List Control Panel Wiring and function

Correct Preparation for Shipment

Electrical Engineering Documentation

Guarding and Saftey

Mechnical Assembly

Mechnical Engineering Documentation

Pneumatic Wiring

Proper Lubrication - Engineering & Services

CAD Software Used Autodesk Inventor

Automation simulation using CAD designing software - Additional Options

Pack Out Systems Carton handling systems with powered or roller conveyors

Stacking

Robotic packaging

Two position carton divertersOperator Interface Touch screen with machine diagnostics and data acquisition

Push button

Message display units

Placard displaysAuxiliary Dial Quality sampling

Vision inspection

Ready to Transform Your Operations?

Contact us today to discuss how our industrial automation equipment and custom automated test equipment can enhance your production capabilities. Our expert team is here to help you design the perfect solution tailored to your needs.