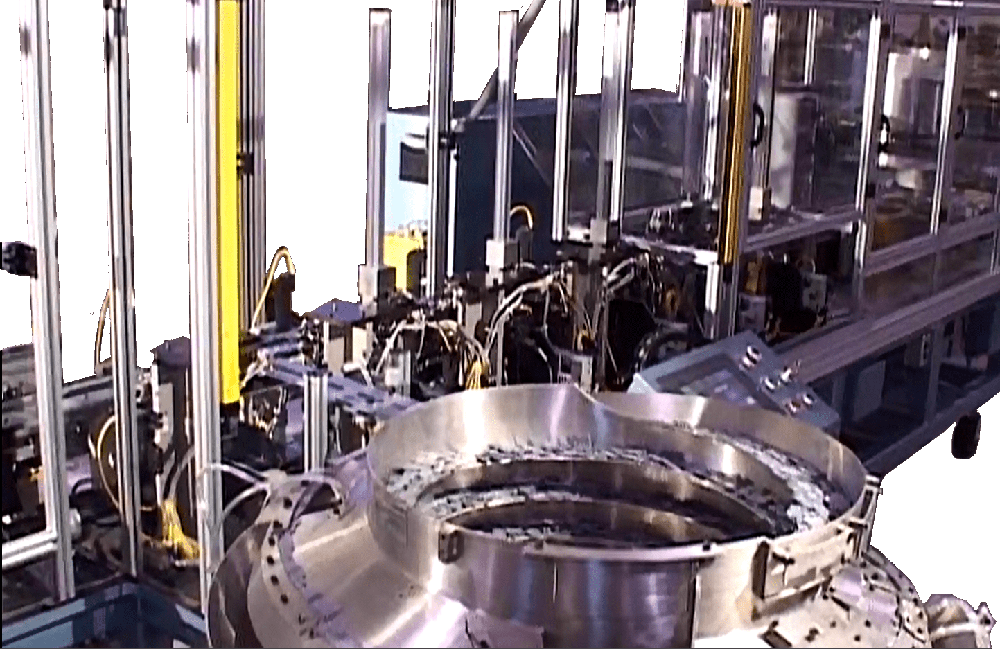

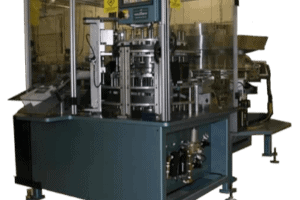

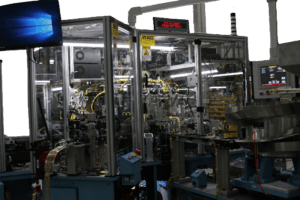

Automated assembly machines for the pharmaceutical and medical industries comply with rigorous standards for performance in control room environments. This type of equipment also follows tooling and finishing specifications that meet or exceed the demands of the industry.

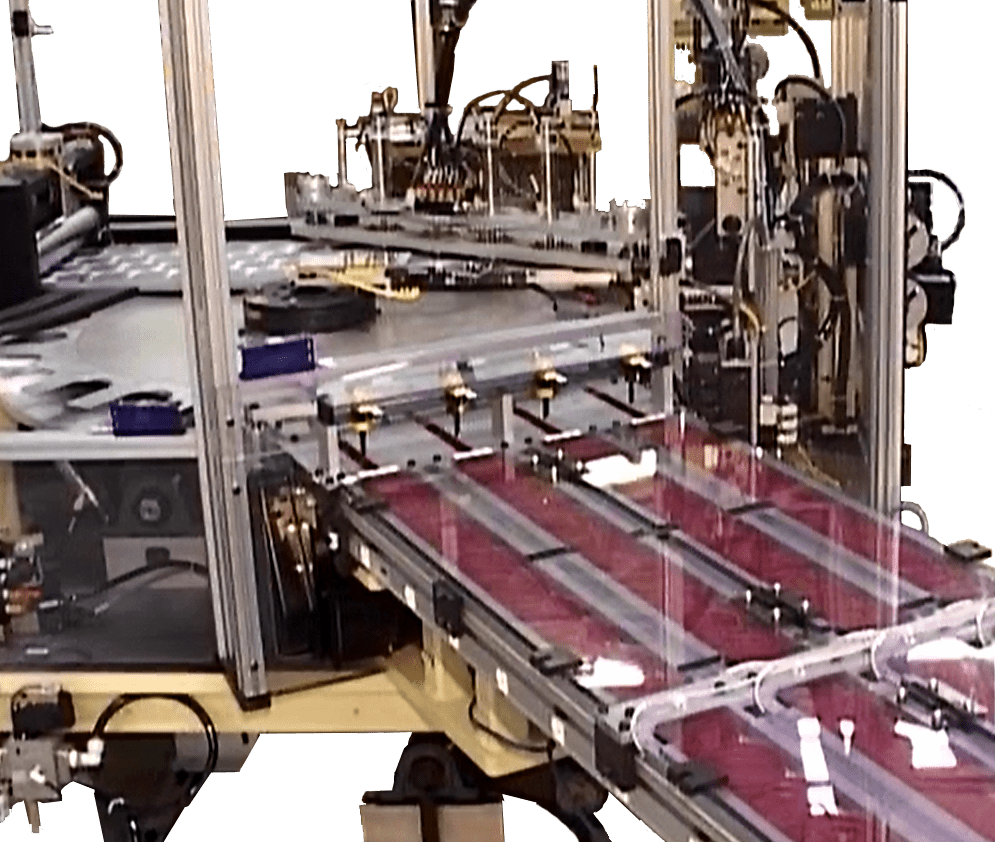

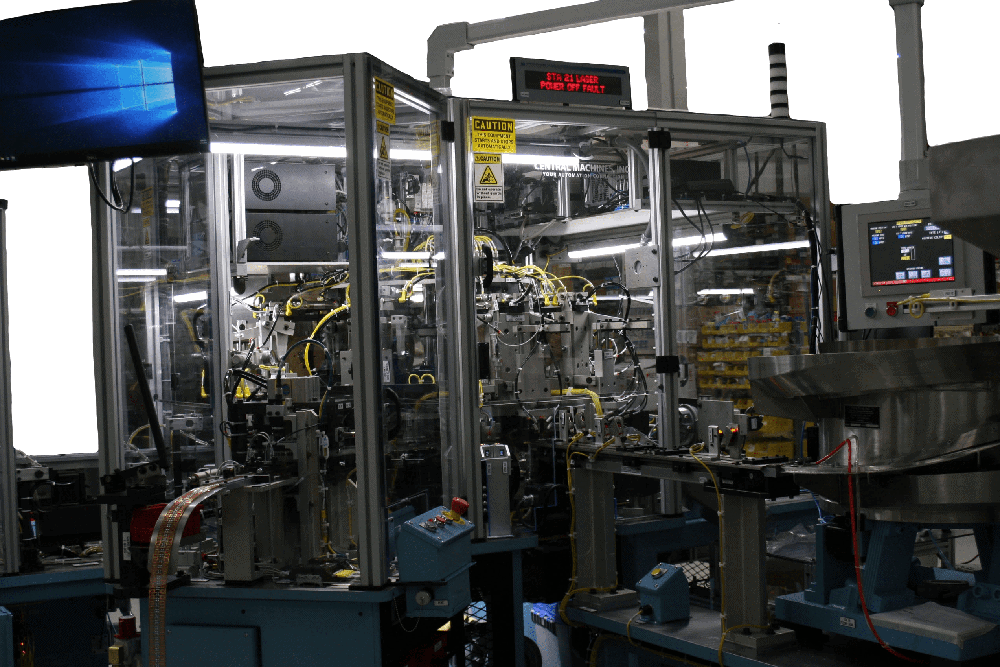

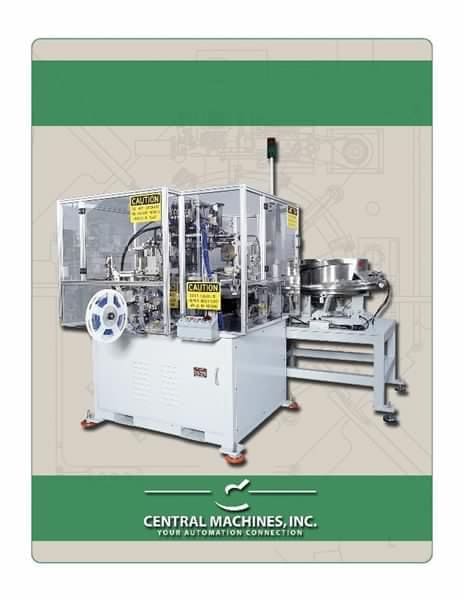

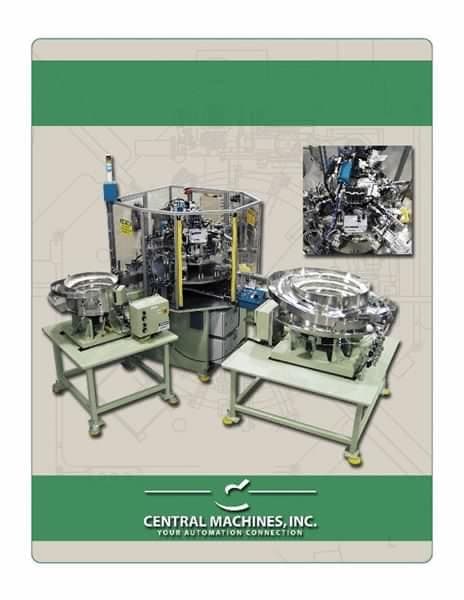

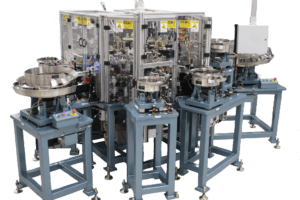

Since 1995, Central Machines, Inc. has manufactured custom assembly machines, filling, part handling, centrifugal feeding, and high-speed vibratory feeding equipment that complies with the high standards of the medical industry. We rely on premium stainless steel for fabricating medical automated assembly machines, and our equipment guards are made of easy to clean and highly transparent clear polycarbonate. With our custom automation equipment, you can achieve output ranges of 20 to 1300 ppm, allowing you to accommodate production volumes of various sizes.

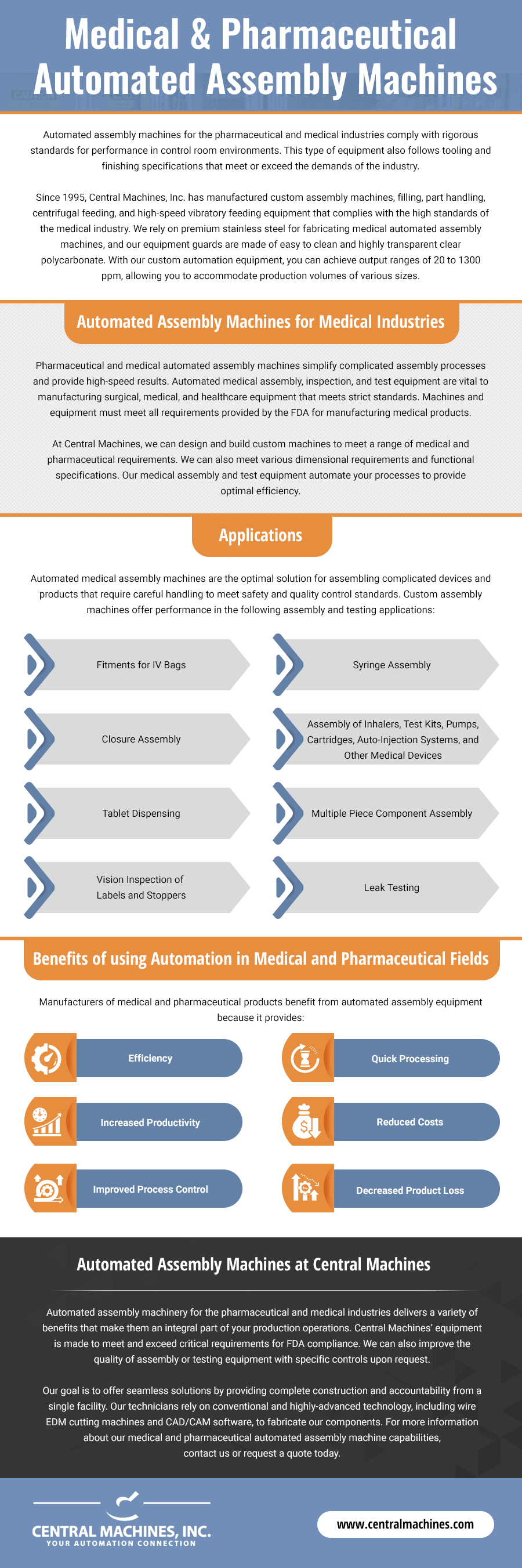

Automated Assembly Machines for Medical Industries

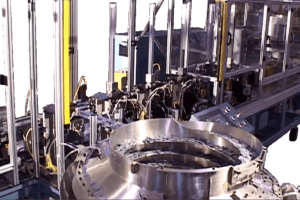

Pharmaceutical and medical automated assembly machines simplify complicated assembly processes and provide high-speed results. Automated medical assembly, inspection, and test equipment are vital to manufacturing surgical, medical, and healthcare equipment that meets strict standards. Machines and equipment must meet all requirements provided by the FDA for manufacturing medical products.

At Central Machines, we can design and build custom machines to meet a range of medical and pharmaceutical requirements. We can also meet various dimensional requirements and functional specifications. Our medical assembly and test equipment automate your processes to provide optimal efficiency.

Applications

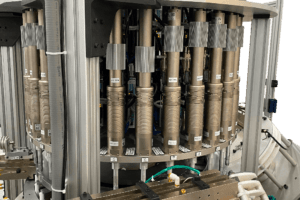

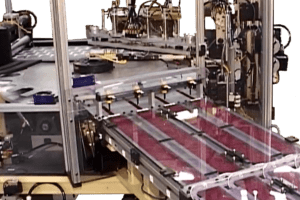

Automated medical assembly machines are the optimal solution for assembling complicated devices and products that require careful handling to meet safety and quality control standards. Custom assembly machines offer performance in the following assembly and testing applications:

- Fitments for IV Bags

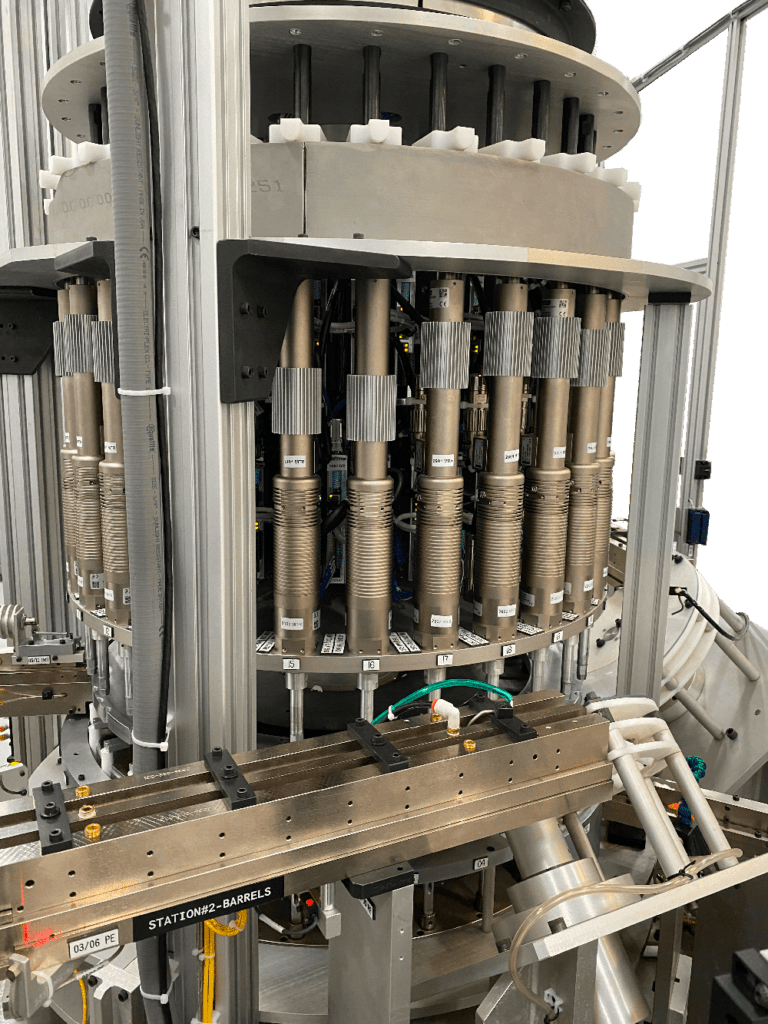

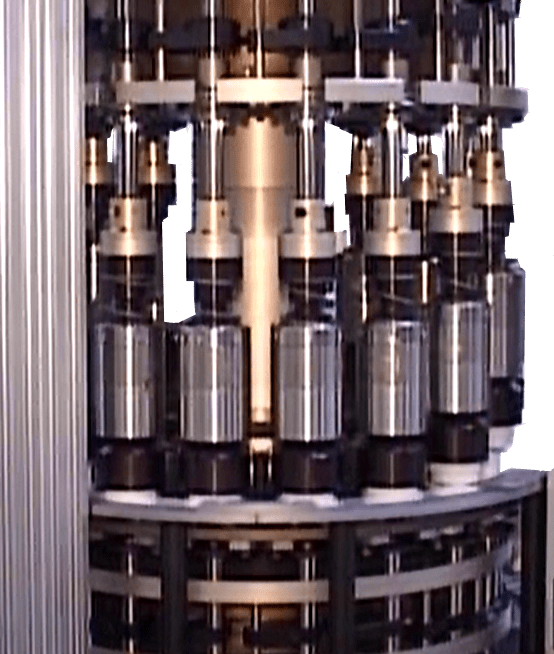

- Syringe Assembly

- Closure Assembly

- Assembly of Inhalers, Test Kits, Pumps, Cartridges, Auto-Injection Systems, and Other Medical Devices

- Tablet Dispensing

- Multiple Piece Component Assembly

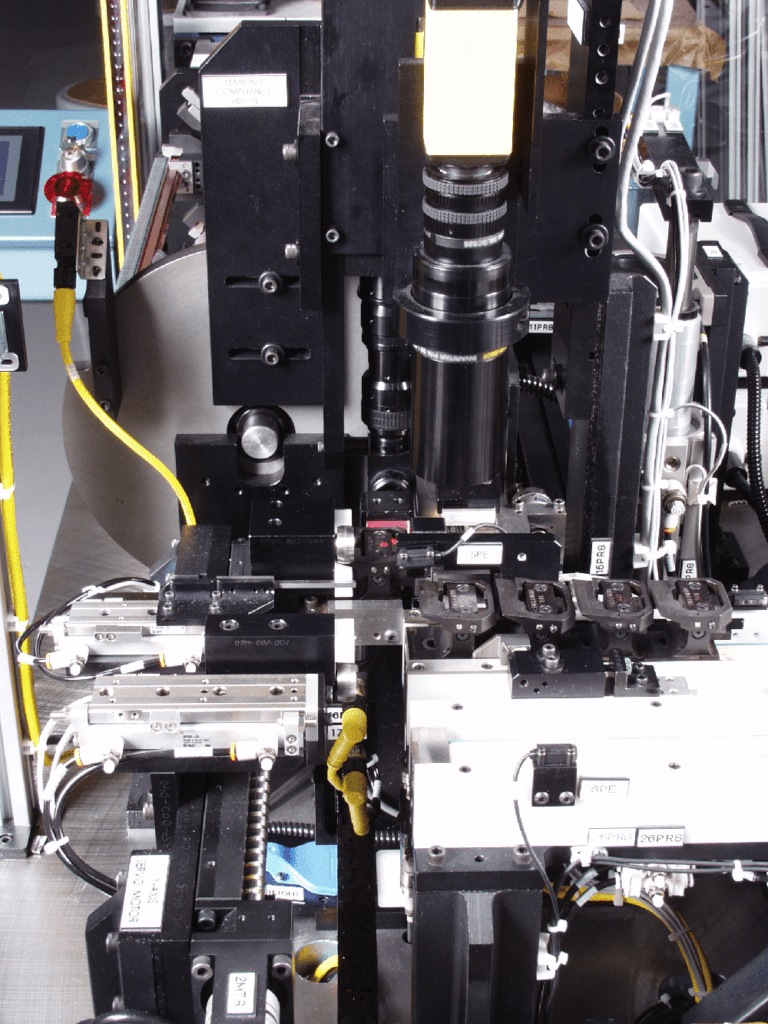

- Vision Inspection of Labels and Stoppers

- Leak Testing

Benefits of using Automation in Medical and Pharmaceutical Fields

Manufacturers of medical and pharmaceutical products benefit from automated assembly equipment because it provides:

- Efficiency. Automation can produce multiple assembled products, inspect products for quality, and run multiple tests simultaneously to increase the overall efficiency of assembly processes and reduce the necessary labor.

- Quick Processing. Automation saves time and produces consistent products faster than a human assembly line.

- Increased Productivity. Since automated machinery can operate at faster speeds and with little human intervention, it can produce a higher output of products in less time. Automated machines also reduce downtime, which further boosts productivity.

- Reduced Costs. Automation reduces labor and time spent on medical device assembly and inspection of products.

- Improved Process Control. Automated machines can provide continuous feedback regarding performance improvement and optimization. This data can be used to make changes that will improve the overall effectiveness and efficiency of a particular process.

- Decreased Product Loss. Automation improves the consistency and quality of finished products by reducing human error.

Automated Assembly Machines at Central Machines

Automated assembly machinery for the pharmaceutical and medical industries delivers a variety of benefits that make them an integral part of your production operations. Central Machines’ equipment is made to meet and exceed critical requirements for FDA compliance. We can also improve the quality of assembly or testing equipment with specific controls upon request.

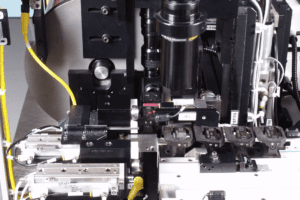

Our goal is to offer seamless solutions by providing complete construction and accountability from a single facility. Our technicians rely on conventional and highly-advanced technology, including wire EDM cutting machines and CAD/CAM software, to fabricate our components. For more information about our medical and pharmaceutical automated assembly machine capabilities, contact us or request a quote today.

Specifications

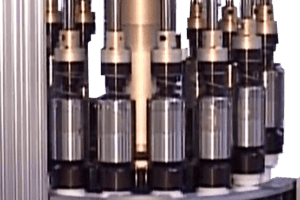

| Applications | IV Bag Fitments Syringe Assembly Closure Assembly Devices Assembly Dispensing Multiple Piece Assembly |

| Types of Machines Available | Continuous Motion Multiple Piece Assembly Machines Continuous Motion Cap Closing Machine Roller Die Liner Machines Pick and Place Machines Carousel Machines Indexing Dial Multiple Piece Assembly Machines Walking Beam Machines Palletized Machines Custom Designed Machines |

| Machine Production Rate | From 20 to 1300 parts per minute |

| Safety Guarding Options | Guarding for pinch points and rotating sections Perimeter guarding with clear polycarbonate panels Electrically interlocked guarding Safety Relays Light Curtain |

| Standards Met | FDA Standards OSHA |

| Post Production Process | Passivation and Inspection |