Why You Should Invest In Automation Equipment

Automated systems and technologies are becoming the prime choice for so many industries. These types of equipment are used to automatically perform production operations in place of human workers by receiving input from a machine operator. Some examples of automated equipment are robots, automation cells, conveyor machines, lifter and turnover machines, and the like.

Many industries benefit from using automated equipment because of its efficiency and process safety boost. Some primary sectors implementing the use of automation equipment include automotive, food and beverage, medical, home and beauty, electronics, and aircraft manufacturers.

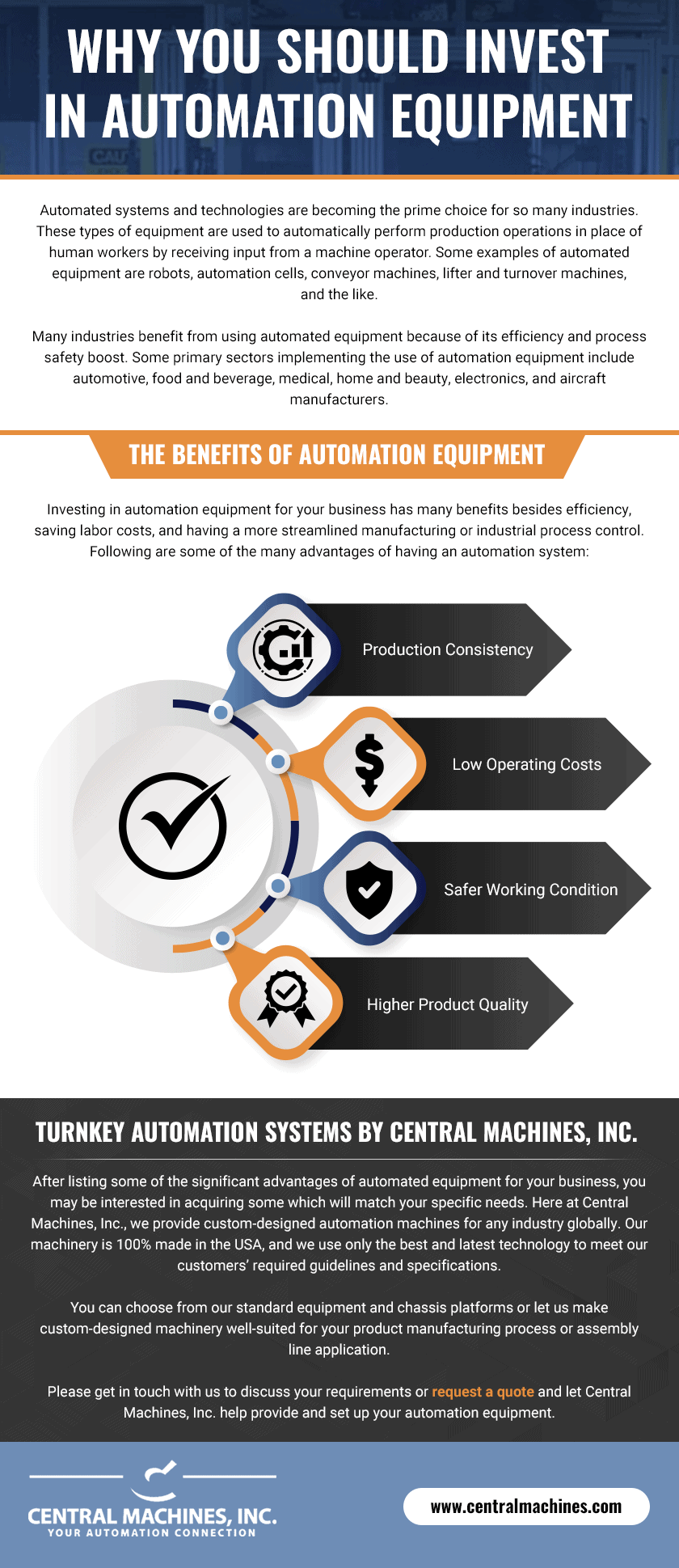

The Benefits Of Automation Equipment

Investing in automation equipment for your business has many benefits besides efficiency, saving labor costs, and having a more streamlined manufacturing or industrial process control. Following are some of the many advantages of having an automation system:

Production Consistency

Compared to humans, automation equipment can perform a far more consistent production in a shorter time. Automation equipment usually performs the manufacturing process with less variability, resulting in consistent product quality. For example, a robot will work at a constant speed, 24/7, without supervision, and still produce the same quality of products round the clock. Thus, opening the door for a larger production volume. Automation equipment can provide consistent product quality and increased production speed, resulting in a better profit for your business.

Low Operating Costs

One automation equipment can perform the tasks of three or more people. It means that you can save on labor costs while also having a streamlined production process that is highly accurate and creates the least amount of material waste, which is also a significant contribution to lowering the operating costs of your business.

Safer Working Condition

Having automation machines helps your workers by removing them from dangerous tasks such as processes that involve extreme temperatures, high forces, excessive pressure, fast movement, and toxic materials. Instead, you can leave your automation equipment to take care of these dangerous tasks, dramatically improving workplace safety for your employees because they are less exposed to work-related injuries.

Higher Product Quality

As we mentioned, automated equipment performs tasks consistently, so the product quality stays consistent. In addition, custom industrial machines and most automated equipment work according to logic and can tell immediately if a specific condition will yield the desired output, making it easy to tweak and improve the quality of a product.

Of course, nothing is perfect. Automated equipment also has some disadvantages, including a high investment cost and the requirement for additional maintenance. However, these disadvantages are outweighed by the many benefits of having automated machines, which is why it is highly recommended that businesses consider enlisting the help of automated equipment.

Turnkey Automation Systems By Central Machines, Inc.

After listing some of the significant advantages of automated equipment for your business, you may be interested in acquiring some which will match your specific needs. Here at Central Machines, Inc., we provide custom-designed automation machines for any industry globally. Our machinery is 100% made in the USA, and we use only the best and latest technology to meet our customers’ required guidelines and specifications.

You can choose from our standard equipment and chassis platforms or let us make custom-designed machinery well-suited for your product manufacturing process or assembly line application.

Please get in touch with us to discuss your requirements or request a quote and let Central Machines, Inc. help provide and set up your automation equipment.