Behind the Scenes: Insights From a Leading Automation Equipment Manufacturer

Technological convergence has sparked a revolution in industrial automation, reshaping production processes from robotics integration to machine vision and AI. As a result, diverse automation equipment such as robots, automation cells, and conveyors are leading the transformation driving efficiency and quality in different industries.

This article explores the journey of Central Machines, Inc., an esteemed automation equipment manufacturer. We will discuss design and development processes, challenges within the industry, and groundbreaking innovations.

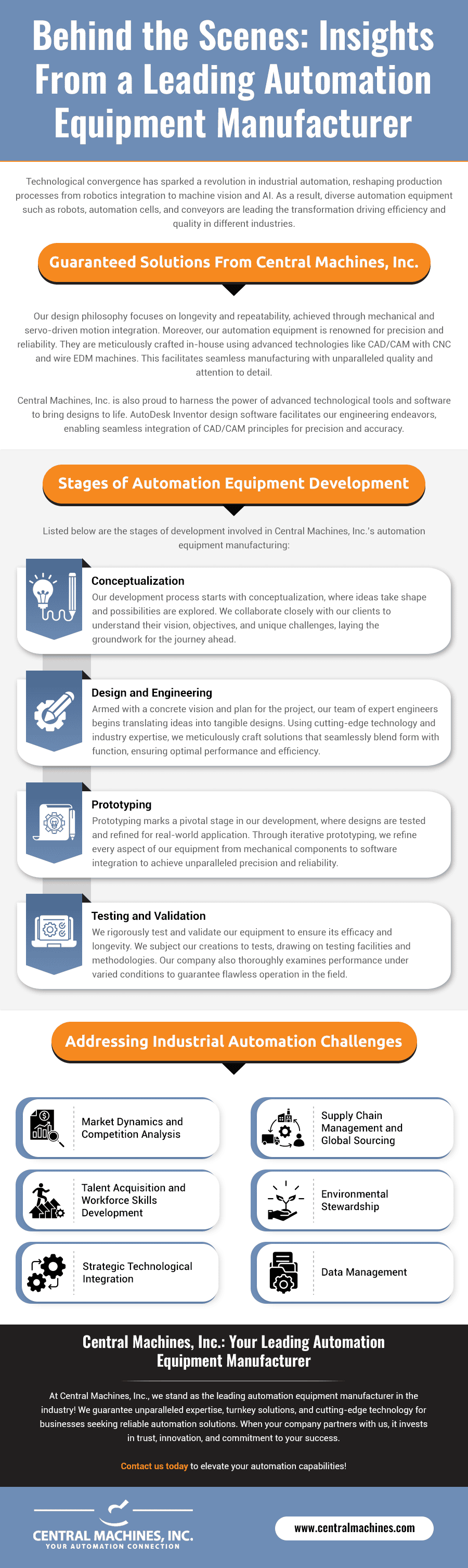

Guaranteed Solutions From Central Machines, Inc.

Our design philosophy focuses on longevity and repeatability, achieved through mechanical and servo-driven motion integration. Moreover, our automation equipment is renowned for precision and reliability. They are meticulously crafted in-house using advanced technologies like CAD/CAM with CNC and wire EDM machines. This facilitates seamless manufacturing with unparalleled quality and attention to detail.

Central Machines, Inc. is also proud to harness the power of advanced technological tools and software to bring designs to life. AutoDesk Inventor design software facilitates our engineering endeavors, enabling seamless integration of CAD/CAM principles for precision and accuracy.

Stages of Automation Equipment Development

Listed below are the stages of development involved in Central Machines, Inc.’s automation equipment manufacturing:

1. Conceptualization

Our development process starts with conceptualization, where ideas take shape and possibilities are explored. We collaborate closely with our clients to understand their vision, objectives, and unique challenges, laying the groundwork for the journey ahead.

2. Design and Engineering

Armed with a concrete vision and plan for the project, our team of expert engineers begins translating ideas into tangible designs. Using cutting-edge technology and industry expertise, we meticulously craft solutions that seamlessly blend form with function, ensuring optimal performance and efficiency.

3. Prototyping

Prototyping marks a pivotal stage in our development, where designs are tested and refined for real-world application. Through iterative prototyping, we refine every aspect of our equipment from mechanical components to software integration to achieve unparalleled precision and reliability.

4. Testing and Validation

We rigorously test and validate our equipment to ensure its efficacy and longevity. We subject our creations to tests, drawing on testing facilities and methodologies. Our company also thoroughly examines performance under varied conditions to guarantee flawless operation in the field.

Addressing Industrial Automation Challenges

Listed below are the innovative solutions addressing unique challenges in the automation equipment manufacturing industry:

Market Dynamics and Competition Analysis

Central Machines, Inc. employs advanced data analytics and market intelligence tools to provide insightful strategies for navigating dynamic market landscapes. By staying ahead of competitors and identifying trends, we enable our clients to maintain a competitive edge and seize new opportunities in the evolving market.

Supply Chain Management and Global Sourcing

We continuously optimize supply chain management through strategic partnerships and innovative sourcing solutions, which streamline logistics and enhance supply chain visibility. This ensures seamless delivery of components and equipment to clients worldwide.

Talent Acquisition and Workforce Skills Development

Our comprehensive training programs and talent retention initiatives cultivate a skilled workforce proficient in the latest automation technologies. By investing in continuous learning and development, we equip our team with the expertise to address evolving industry demands and drive innovation.

Environmental Stewardship

Central Machines, Inc. prioritizes environmental sustainability in our design and manufacturing processes. Through eco-friendly design principles and sustainable manufacturing, we minimize our ecological footprint and contribute to a greener future for our clients and the planet.

Strategic Technological Integration

Balancing reliance on technology is key to successful automation implementation. At Central Machines, Inc., we advocate for strategic technology integration that utilizes automation as an enabler rather than fostering dependency. Our comprehensive approach ensures business continuity and resilience despite technological disruptions.

Data Management

Our advanced data analytics platforms and real-time monitoring systems enable comprehensive data management and analysis. By harnessing the power of data-driven insights, we enhance reliability and drive continuous improvement across our automation solutions.

Central Machines, Inc.: Your Leading Automation Equipment Manufacturer

At Central Machines, Inc., we stand as the leading automation equipment manufacturer in the industry! We guarantee unparalleled expertise, turnkey solutions, and cutting-edge technology for businesses seeking reliable automation solutions. When your company partners with us, it invests in trust, innovation, and commitment to your success.

Contact us today to elevate your automation capabilities!