Central Machines, Inc. is a trusted name among industrial automation equipment manufacturers, offering custom-built systems that support high-volume, high-precision production.

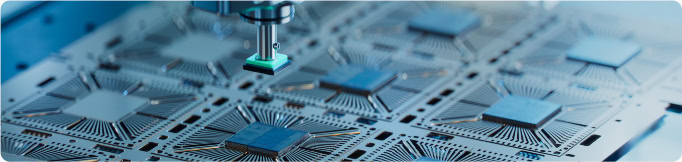

With decades of engineering experience and a fully integrated U.S.-based facility, we develop dependable automation machinery for a wide range of industries. From medical components and electronics assembly to household products and food packaging, Central Machines brings automation to every phase of the assembly process. Each system is engineered with a focus on practical application, durability, speed, and flexibility—enabling clients to boost output, reduce error, and maintain strict quality control.