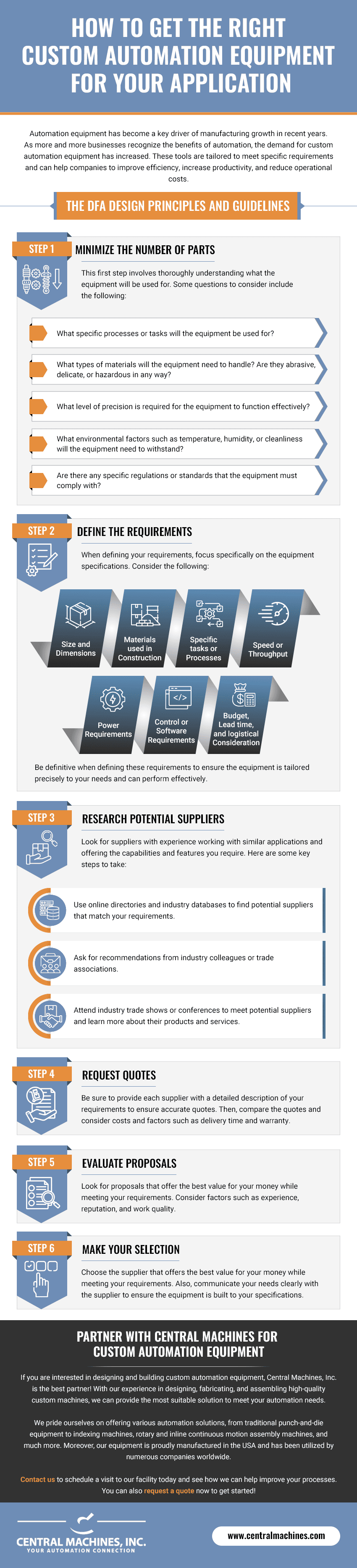

How To Get the Right Custom Automation Equipment for Your Application

Automation equipment has become a key driver of manufacturing growth in recent years. As more and more businesses recognize the benefits of automation, the demand for custom automation equipment has increased. These tools are tailored to meet specific requirements and can help companies to improve efficiency, increase productivity, and reduce operational costs.

This article will discuss the steps for getting your applications custom automation equipment.

Step 1: Understand the Application

This first step involves thoroughly understanding what the equipment will be used for. Some questions to consider include the following:

- What specific processes or tasks will the equipment be used for?

- What types of materials will the equipment need to handle? Are they abrasive, delicate, or hazardous in any way?

- What level of precision is required for the equipment to function effectively?

- What environmental factors such as temperature, humidity, or cleanliness will the equipment need to withstand?

- Are there any specific regulations or standards that the equipment must comply with?

Answering these questions will guide you to better understand your applications needs.

Step 2: Define the Requirements

When defining your requirements, focus specifically on the equipment specifications. Consider the following:

- Size and dimensions

- Materials used in construction

- Specific tasks or processes

- Speed or throughput

- Power requirements

- Control or software requirements

- Budget, lead time, and logistical considerations

Be definitive when defining these requirements to ensure the equipment is tailored precisely to your needs and can perform effectively.

Step 3: Research Potential Suppliers

Look for suppliers with experience working with similar applications and offering the capabilities and features you require. Here are some key steps to take:

- Use online directories and industry databases to find potential suppliers that match your requirements.

- Ask for recommendations from industry colleagues or trade associations.

- Attend industry trade shows or conferences to meet potential suppliers and learn more about their products and services.

Step 4: Request Quotes

Be sure to provide each supplier with a detailed description of your requirements to ensure accurate quotes. Then, compare the quotes and consider costs and factors such as delivery time and warranty.

Step 5: Evaluate Proposals

Look for proposals that offer the best value for your money while meeting your requirements. Consider factors such as experience, reputation, and work quality.

Step 6: Make Your Selection

Choose the supplier that offers the best value for your money while meeting your requirements. Also, communicate your needs clearly with the supplier to ensure the equipment is built to your specifications.

Partner With Central Machines for Custom Automation Equipment

If you are interested in designing and building custom automation equipment, Central Machines, Inc. is the best partner! With our experience in designing, fabricating, and assembling high-quality custom machines, we can provide the most suitable solution to meet your automation needs.

We pride ourselves on offering various automation solutions, from traditional punch-and-die equipment to indexing machines, rotary and inline continuous motion assembly machines, and much more. Moreover, our equipment is proudly manufactured in the USA and has been utilized by numerous companies worldwide.

Contact us to schedule a visit to our facility today and see how we can help improve your processes. You can also request a quote now to get started!