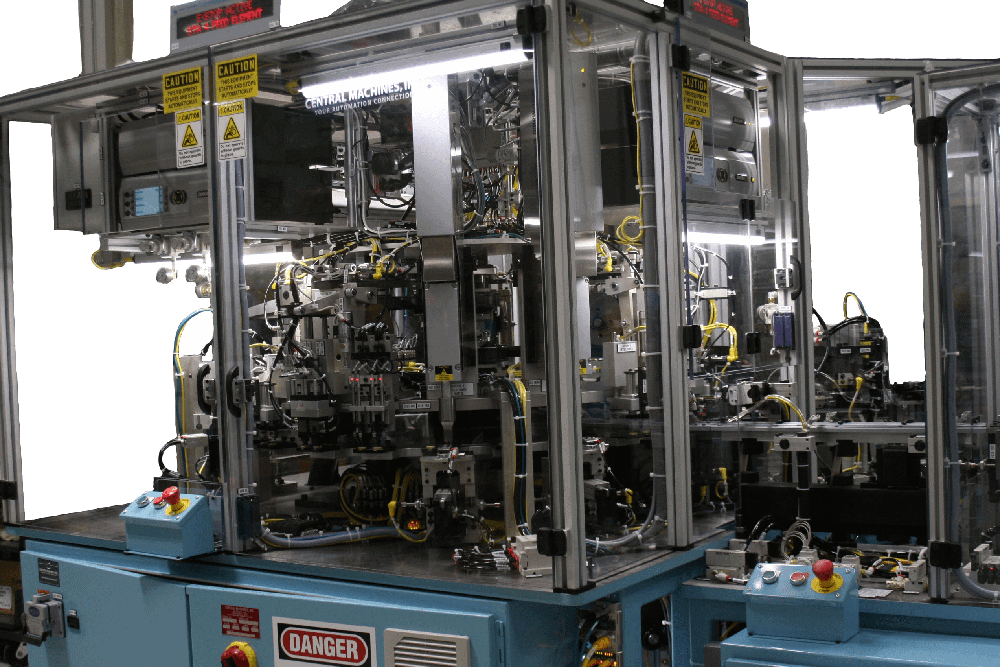

At Central Machines, Inc., we build fully automated industrial assembly equipment that helps manufacturers produce faster, smarter, and more efficiently. As one of the trusted industrial automation equipment manufacturers, we focus on creating systems that meet specific production goals while maintaining reliability and precision.

Experience That Delivers Results

For decades, Central Machines, Inc. has been helping companies automate their assembly lines with high-speed, precision-built systems. Our team of engineers and technicians brings hands-on experience to every project, making sure each machine performs consistently on the production floor. We handle everything—from concept and design to assembly, wiring, programming, and installation—so you can have a complete automation solution from one source.

Expertise in Custom Automation Equipment

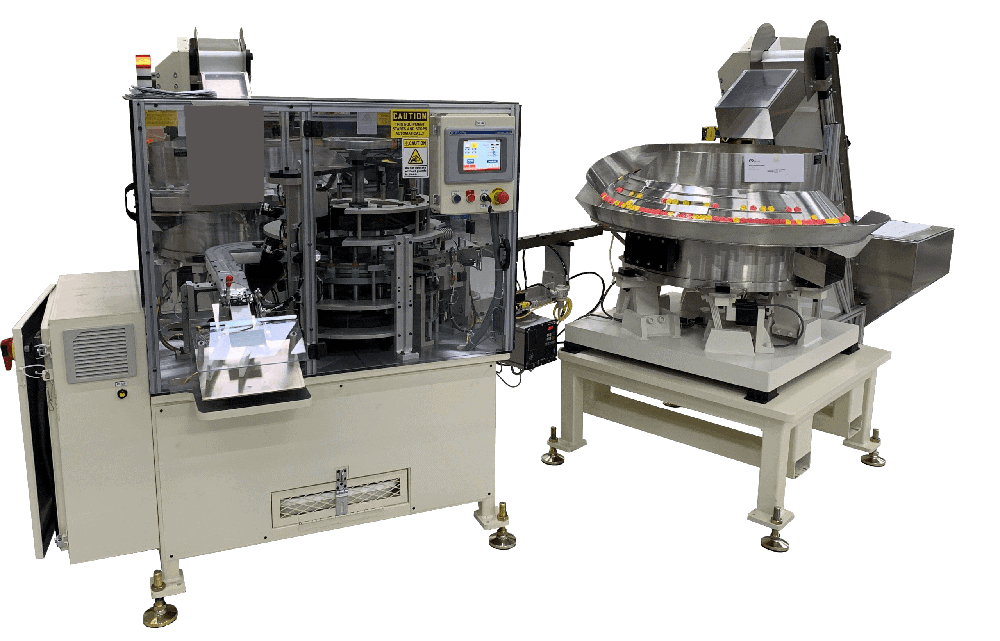

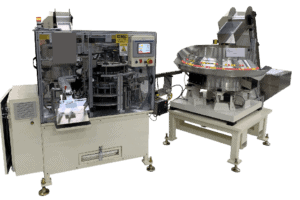

Every manufacturing process is different. That’s why we specialize in custom automation equipment built to match your exact production requirements. Whether you need a machine that assembles small medical components or a system that handles plastic closures at thousands of pieces per minute, we can design and build it in-house. Our engineers work closely with you to understand production needs, speed goals, and quality standards before developing a solution that fits.

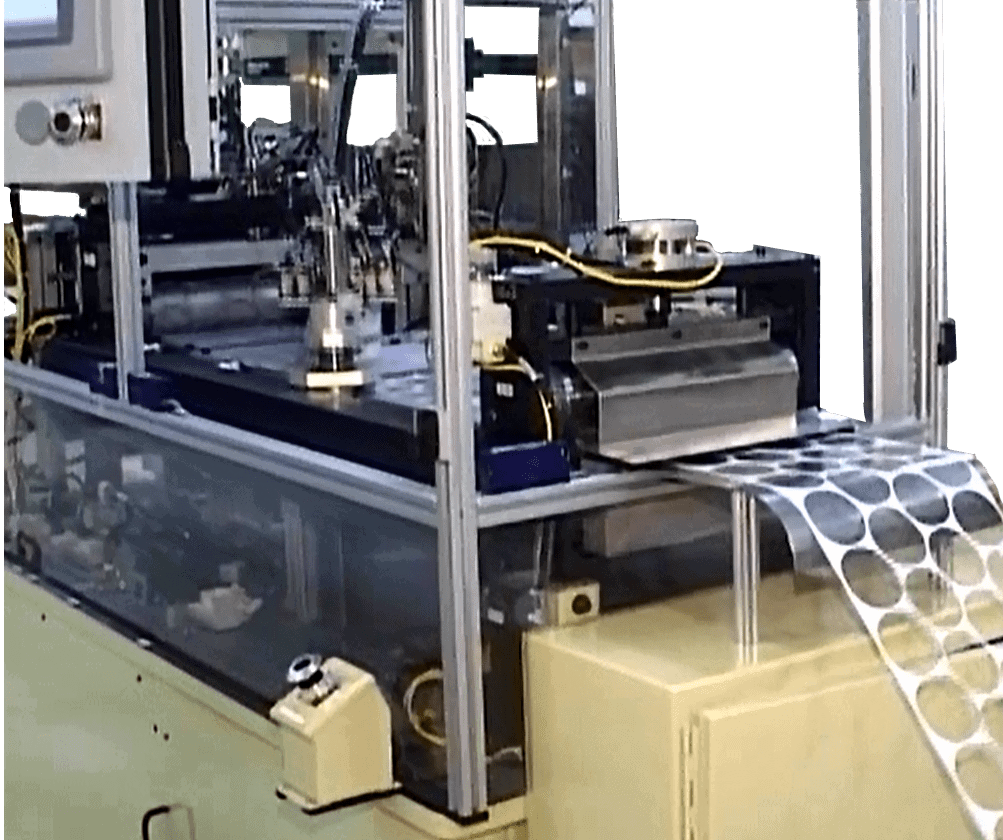

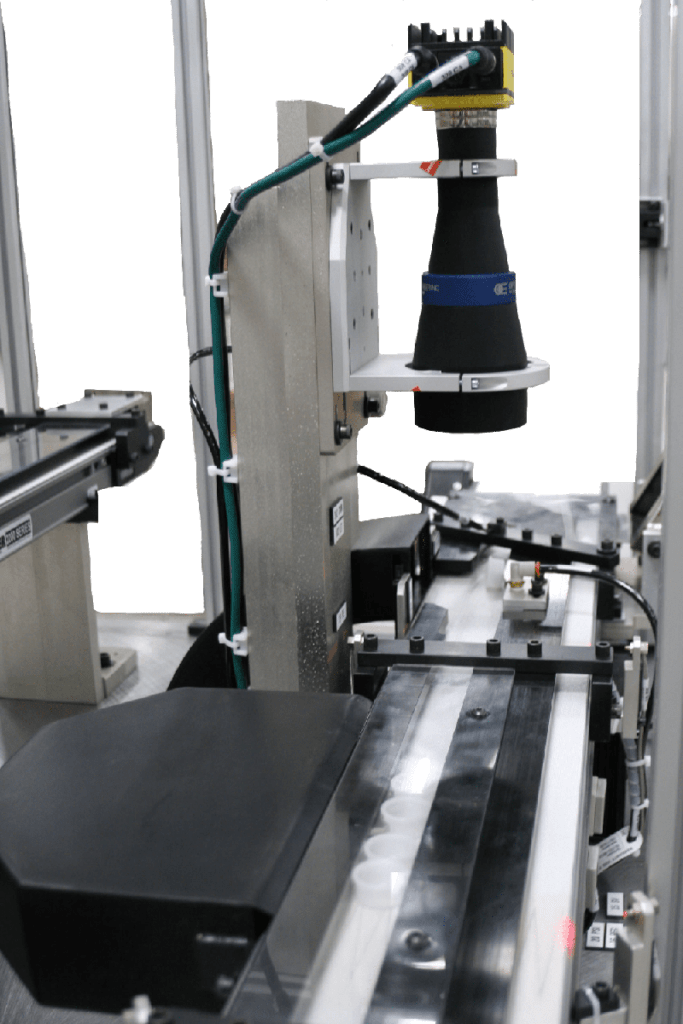

We have experience across a wide range of industries, including medical, packaging, electronics, and automotive manufacturing. Each project benefits from our ability to integrate advanced controls, sensors, and machine vision technology, allowing for faster production and fewer defects.

Advanced Assembly Automation Equipment

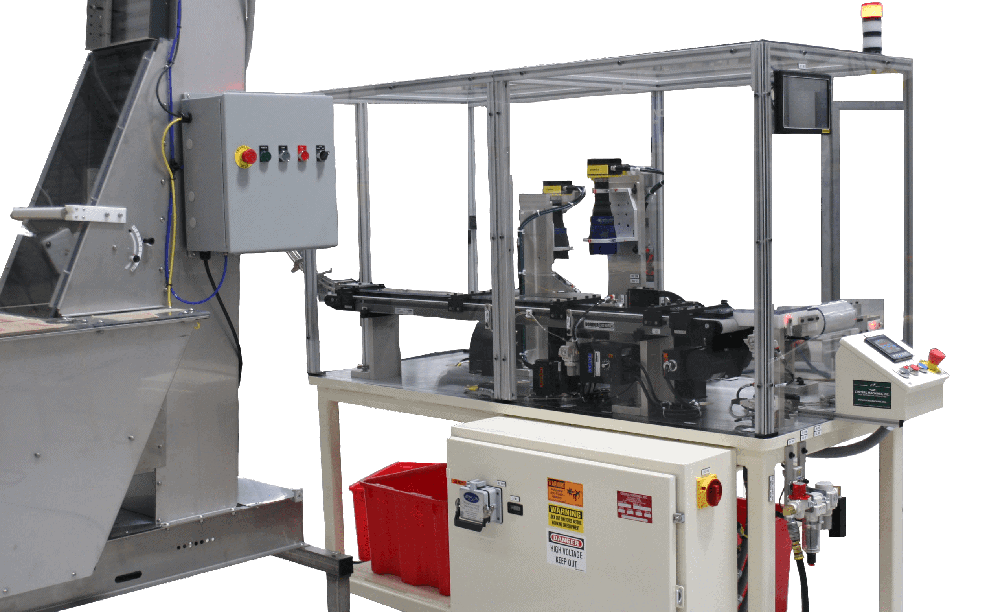

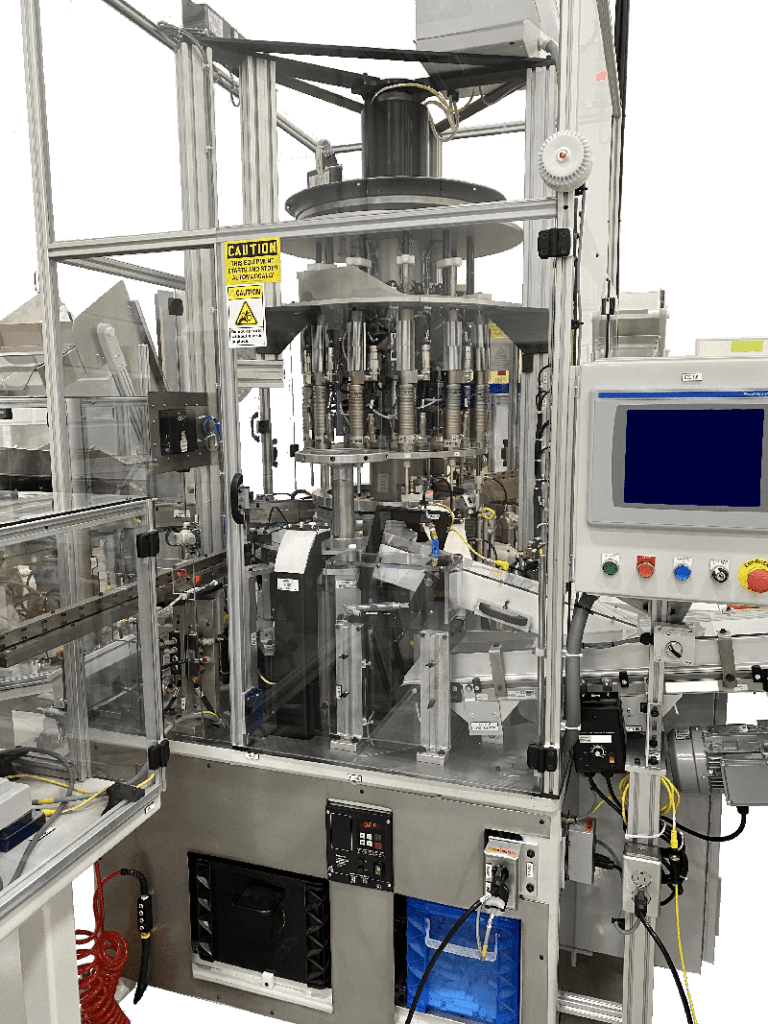

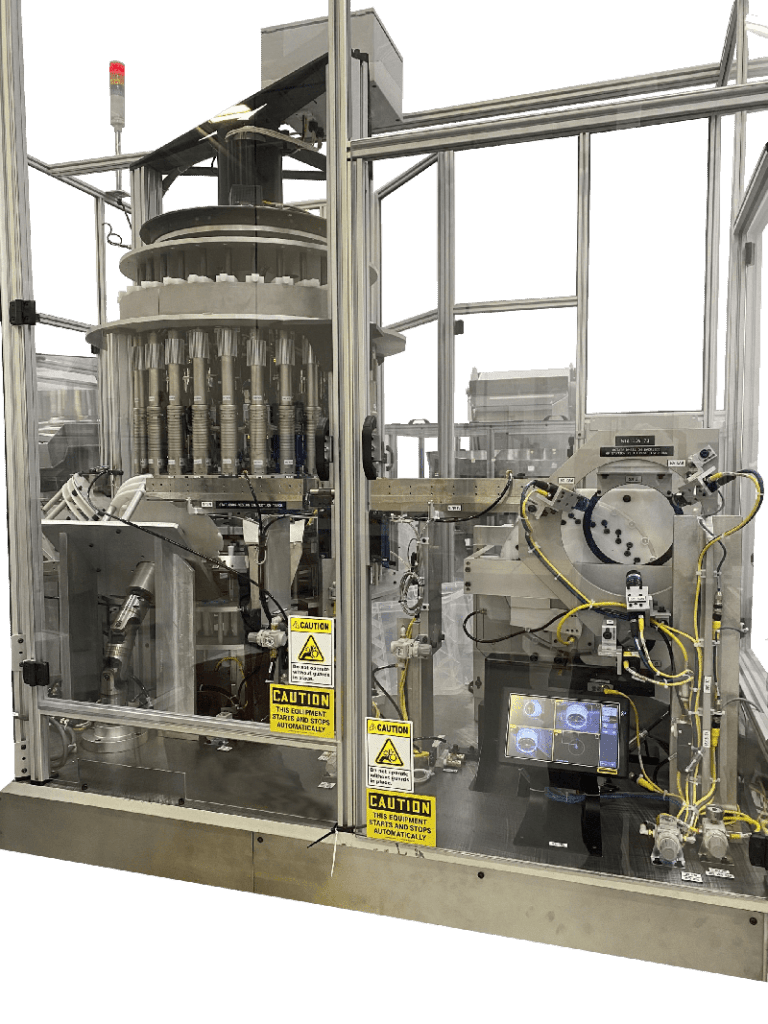

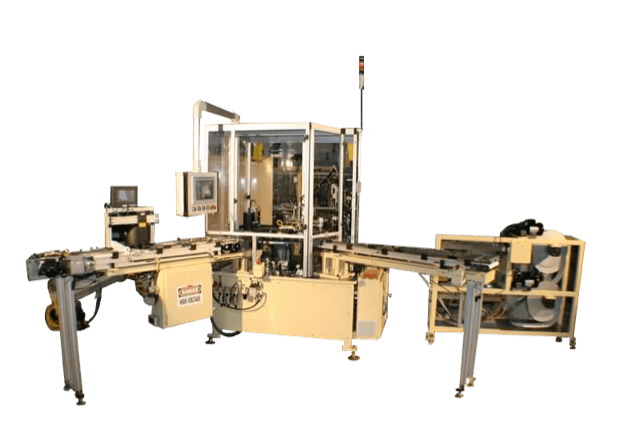

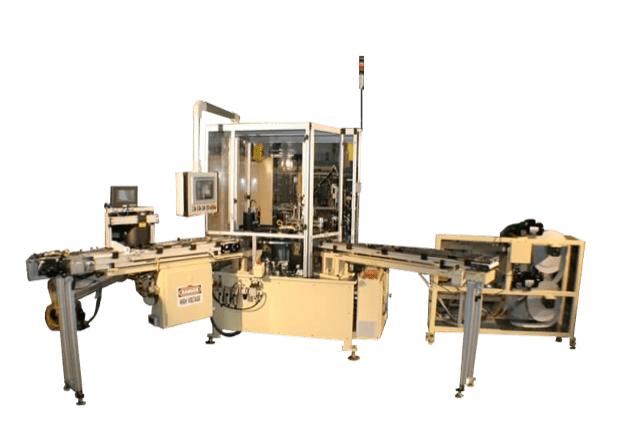

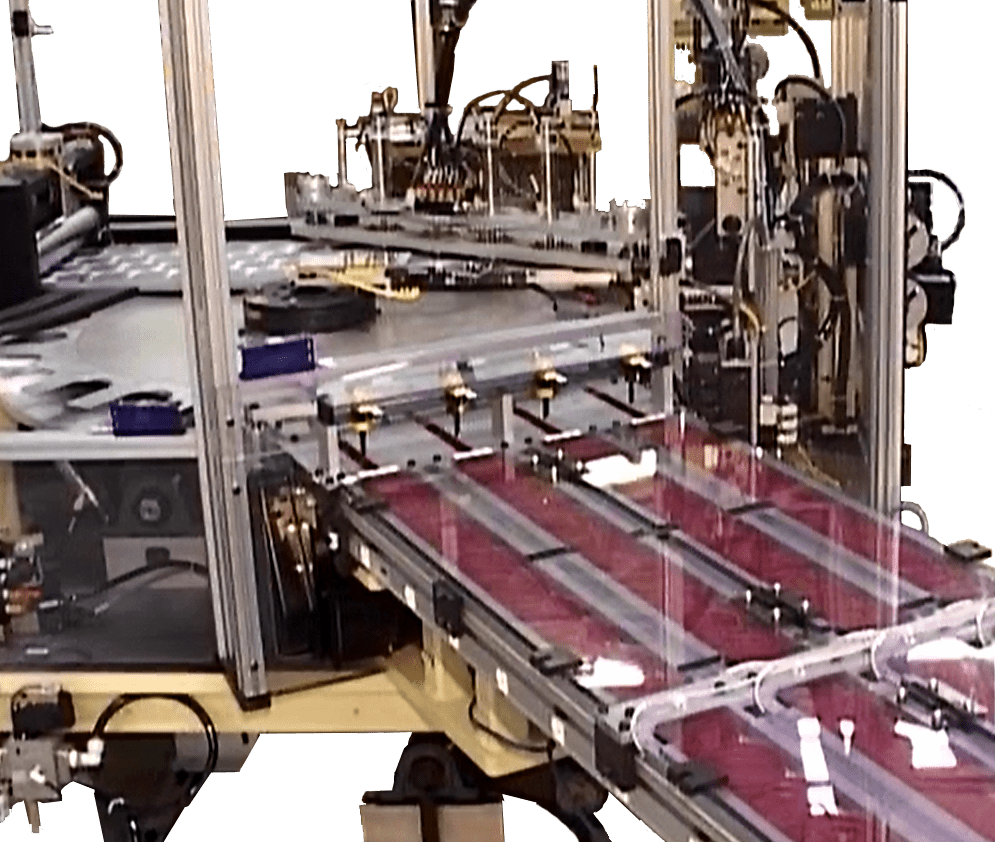

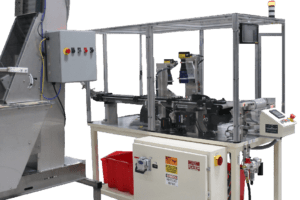

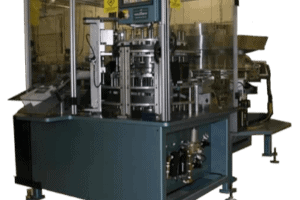

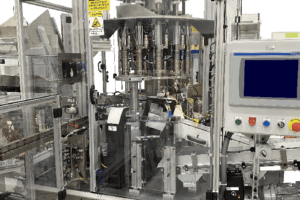

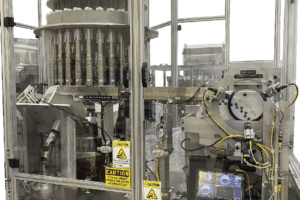

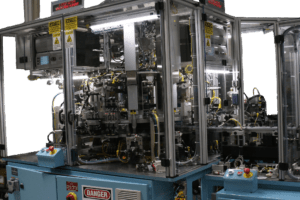

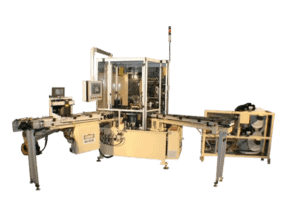

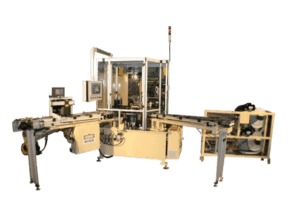

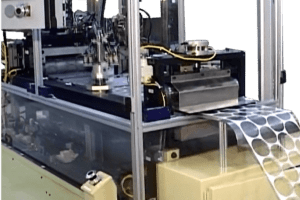

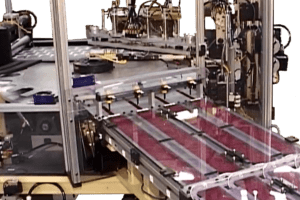

Central Machines builds several types of assembly automation equipment, including continuous motion systems, indexing dial machines, and cap lining and closing machines. We also design servo-driven and robotic transfer systems for handling complex part movements.

Our systems combine mechanical precision with electronic control. Touchscreen interfaces give operators easy access to setup and performance data, while built-in inspection systems maintain consistent product quality. With some machines capable of speeds up to 1,300 parts per minute, we help manufacturers meet demanding production targets without sacrificing accuracy.

In-House Manufacturing Capabilities

All automation equipment is designed, fabricated, and assembled in our Lincolnshire, Illinois facility. We have a complete machine shop equipped for CNC machining, EDM, milling, welding, and precision tooling. By building everything ourselves, we maintain full control over quality and performance. Tight tolerances, durable construction, and consistent testing are part of every project we deliver.

Serving a Range of Industries

Our fully automated assembly equipment is used across multiple industries:

- Medical and Pharmaceutical – For assembling precision parts and packaging components

- Consumer Products – For producing caps, closures, and dispensers

- Electronics and Automotive – For small component assembly and inspection

- Packaging and Plastics – For lining, sealing, and high-speed closure operations

Each industry benefits from automation that increases productivity, reduces manual labor, and maintains consistent quality.

Why Partner with Central Machines, Inc.

Companies choose Central Machines because we build machines that work reliably day after day. Our equipment helps reduce production costs, shorten cycle times, and improve product consistency. As one of the top industrial automation equipment manufacturers, we focus on long-term performance and support. From system design to operator training, we help clients keep their operations running smoothly.

Our process is simple and transparent:

- Discuss your automation goals

- Develop a system design that meets your requirements

- Manufacture and assemble the equipment in-house

- Program and test each function before delivery

- Install, train, and provide ongoing support

Every project receives careful planning and precise execution, resulting in reliable automation that delivers measurable results.

If you’re looking to upgrade production or replace outdated systems, Central Machines, Inc. can help. Contact us today to learn more about our custom automation equipment and see how our assembly automation equipment can improve your manufacturing process.