Types of Automated Assembly Machines

Automation entails a controller comparing a measured state to a list of ideal values and adjusting it to preserve the desired conditions. While automation initially involved mechanical controls, technological advancement allowed it to move past that and use electronic and computer controls based on advanced programming languages. Today, it is commonly associated with integrating computers with electrical, hydraulic, structural, and pneumatic devices.

Manufacturing automation is a production system that automates tasks, processes, and development through technology. Its goal is to increase industrial production more quickly and effectively than humans previously could. This system also increases performance efficiency by allocating fewer hours to the production process and more to the design, operation, installation, and troubleshooting of automated machines, robots, and equipment.

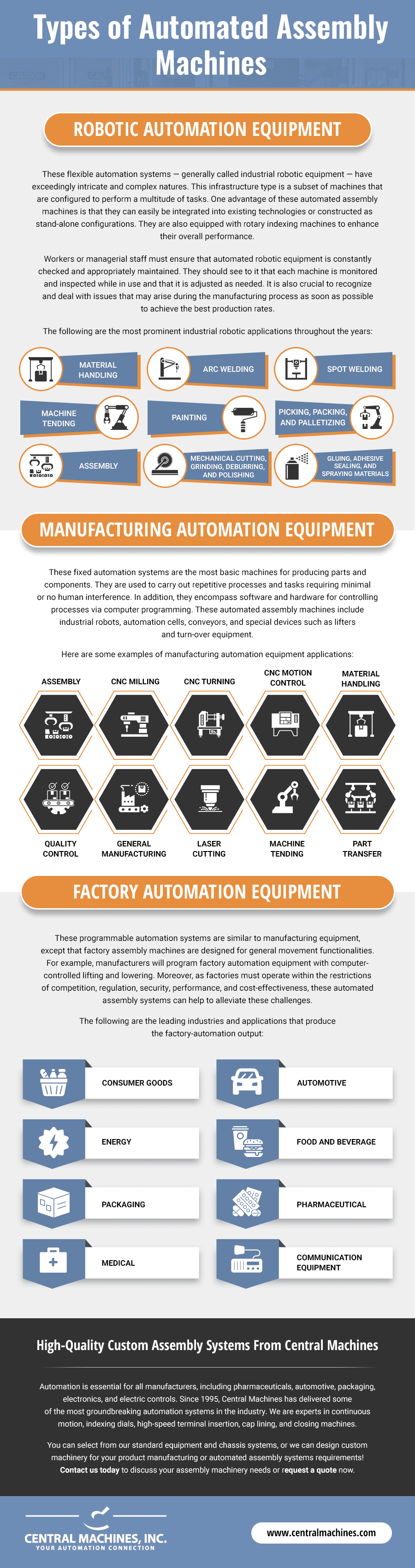

This article will go through the three types of automated assembly machines: robotic, manufacturing, and factory automation.

Robotic Automation Equipment

These flexible automation systems — generally called industrial robotic equipment — have exceedingly intricate and complex natures. This infrastructure type is a subset of machines that are configured to perform a multitude of tasks. One advantage of these automated assembly machines is that they can easily be integrated into existing technologies or constructed as stand-alone configurations. They are also equipped with rotary indexing machines to enhance their overall performance.

Workers or managerial staff must ensure that automated robotic equipment is constantly checked and appropriately maintained. They should see to it that each machine is monitored and inspected while in use and that it is adjusted as needed. It is also crucial to recognize and deal with issues that may arise during the manufacturing process as soon as possible to achieve the best production rates.

The following are the most prominent industrial robotic applications throughout the years:

- Material handling

- Arc welding

- Spot welding

- Machine tending

- Painting

- Picking, packing, and palletizing

- Assembly

- Mechanical cutting, grinding, deburring, and polishing

- Gluing, adhesive sealing, and spraying materials

Manufacturing Automation Equipment

These fixed automation systems are the most basic machines for producing parts and components. They are used to carry out repetitive processes and tasks requiring minimal or no human interference. In addition, they encompass software and hardware for controlling processes via computer programming. These automated assembly machines include industrial robots, automation cells, conveyors, and special devices such as lifters and turn-over equipment.

Here are some examples of manufacturing automation equipment applications:

- Assembly

- CNC milling

- CNC turning

- CNC motion control

- Material handling

- Quality control

- General manufacturing

- Laser cutting

- Machine tending

- Part transfer

Factory Automation Equipment

These programmable automation systems are similar to manufacturing equipment, except that factory assembly machines are designed for general movement functionalities. For example, manufacturers will program factory automation equipment with computer-controlled lifting and lowering. Moreover, as factories must operate within the restrictions of competition, regulation, security, performance, and cost-effectiveness, these automated assembly systems can help to alleviate these challenges.

The following are the leading industries and applications that produce the factory-automation output:

- Consumer goods

- Automotive

- Energy

- Food and beverage

- Packaging

- Pharmaceutical

- Medical

- Communication equipment

High-Quality Custom Assembly Systems From Central Machines

Automation is essential for all manufacturers, including pharmaceuticals, automotive, packaging, electronics, and electric controls. Since 1995, Central Machines has delivered some of the most groundbreaking automation systems in the industry. We are experts in continuous motion, indexing dials, high-speed terminal insertion, cap lining, and closing machines.

You can select from our standard equipment and chassis systems, or we can design custom machinery for your product manufacturing or automated assembly systems requirements! Contact us today to discuss your assembly machinery needs or request a quote now.