The food and beverage industry faces many challenges in meeting rising consumer demand and expectations for rapid production. Companies also have to factor in rising material and food costs. Given the strict industry regulations for the quality and safe handling of consumables, the food and beverage sector cannot sacrifice quality for quantity. To combat these issues, the industry depends on reliable equipment that can increase yield and operational efficiency while also offering consistent performance, quality, and safety. Automated assembly is an ideal solution for meeting these needs.

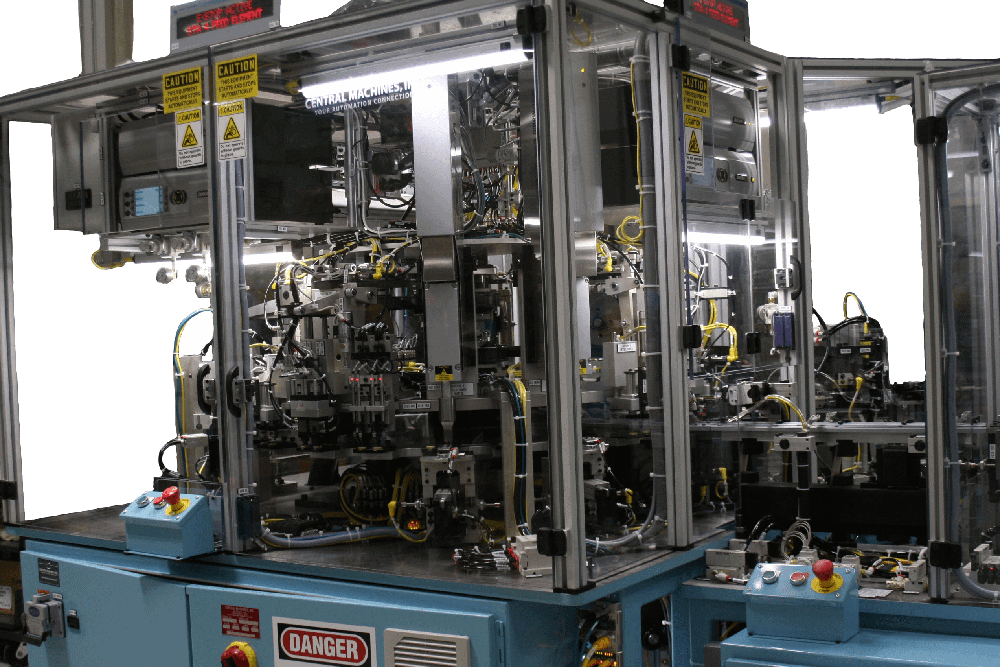

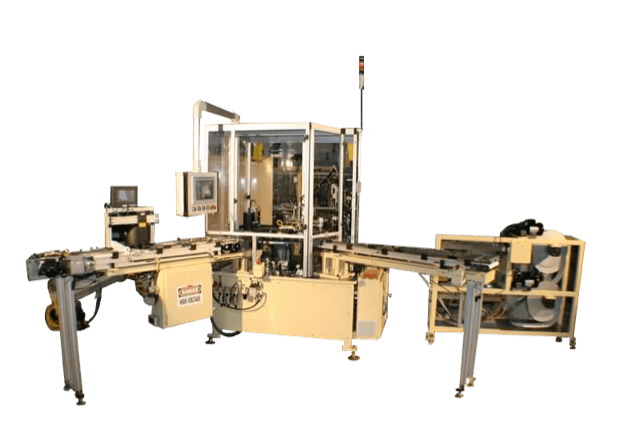

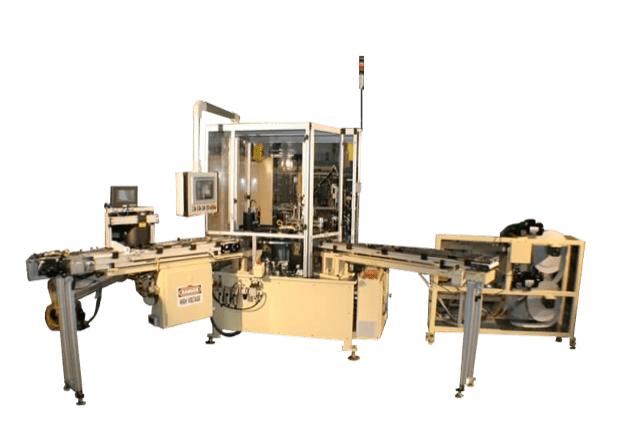

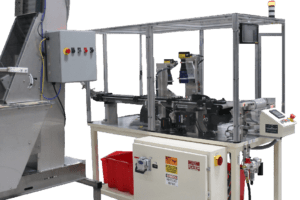

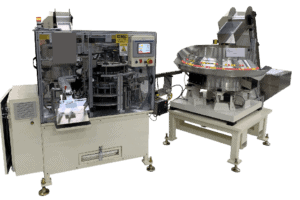

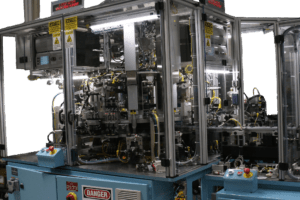

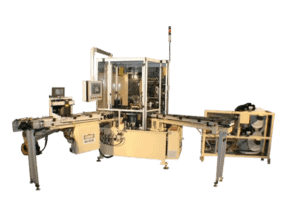

Central Machines, Inc. has extensive experience building and manufacturing custom equipment, including entire dispensing units, packaging units, and cap closing units. We also have a standard set of machine chassis that we’ve configured for our most requested assembly applications. Our team works closely with customers to find the right automated assembly equipment solution to support their business.

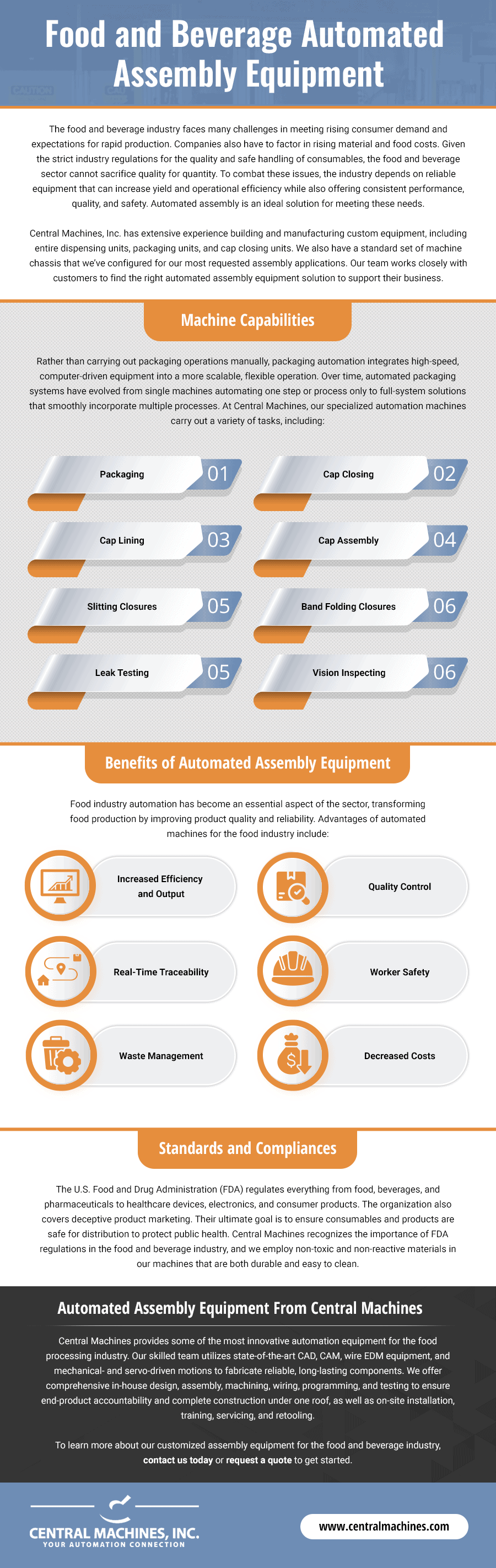

Machine Capabilities

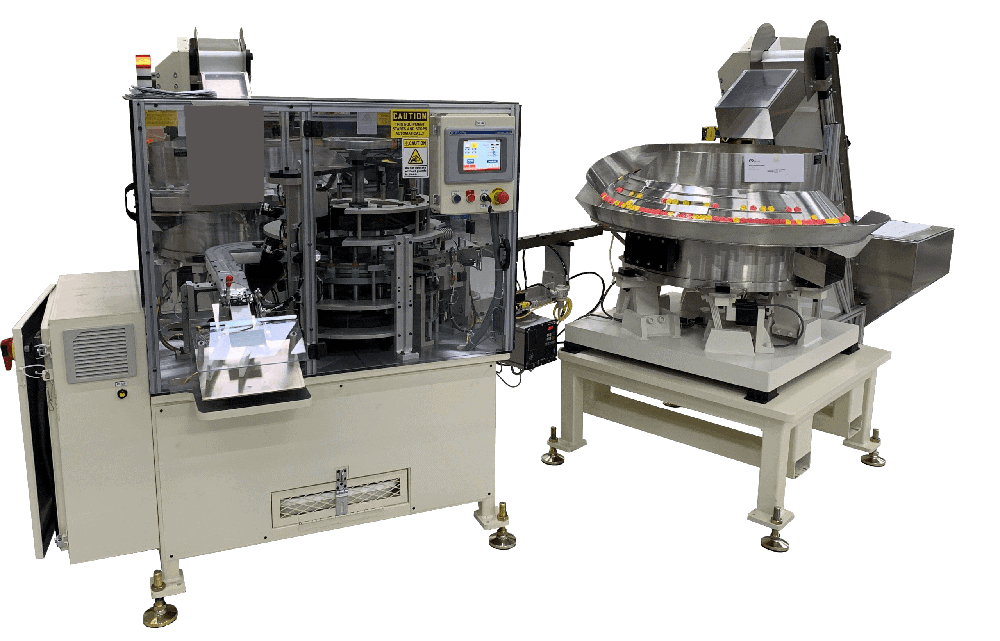

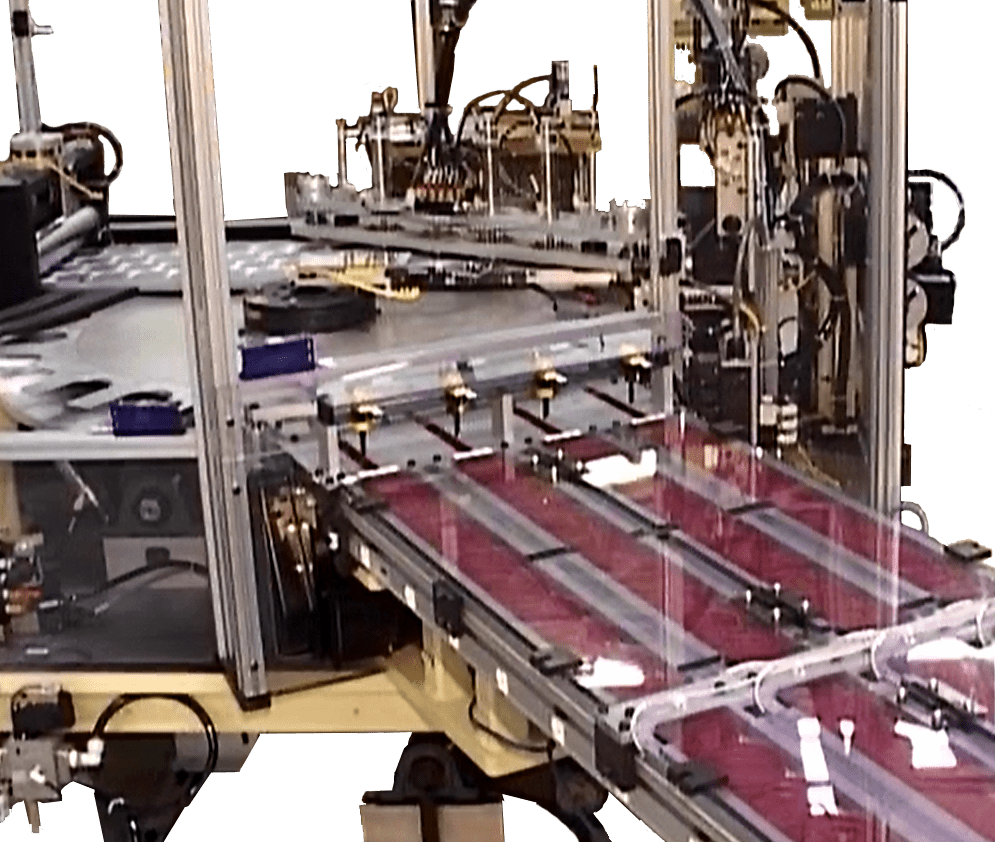

Rather than carrying out packaging operations manually, packaging automation integrates high-speed, computer-driven equipment into a more scalable, flexible operation. Over time, automated packaging systems have evolved from single machines automating one step or process only to full-system solutions that smoothly incorporate multiple processes. At Central Machines, our specialized automation machines carry out a variety of tasks, including:

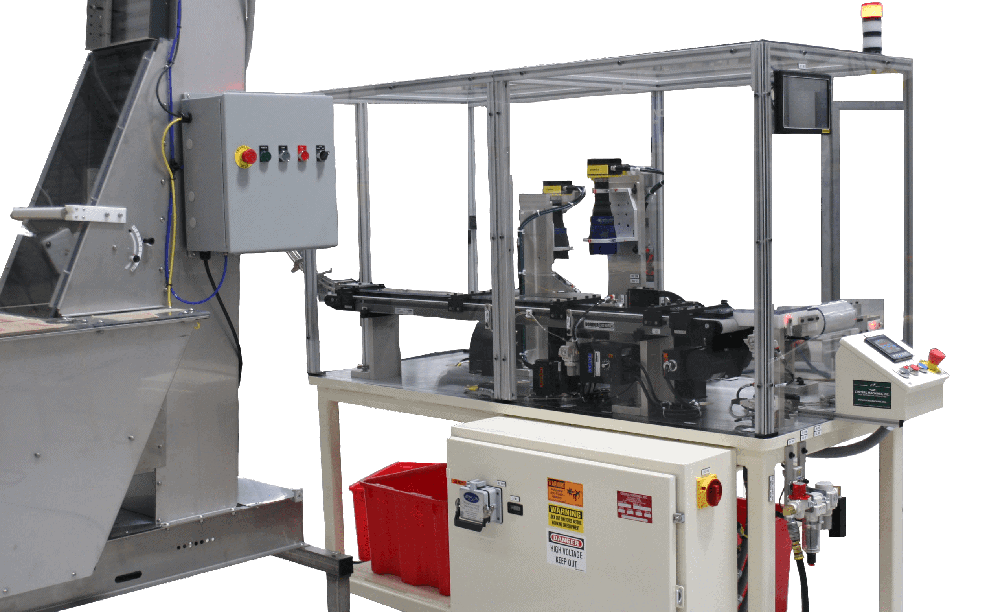

- Packaging. Central Machines can custom-manufacture packaging units to fit clients’ specifications for machine rate, feeder type, safety guarding options, and testing processes.

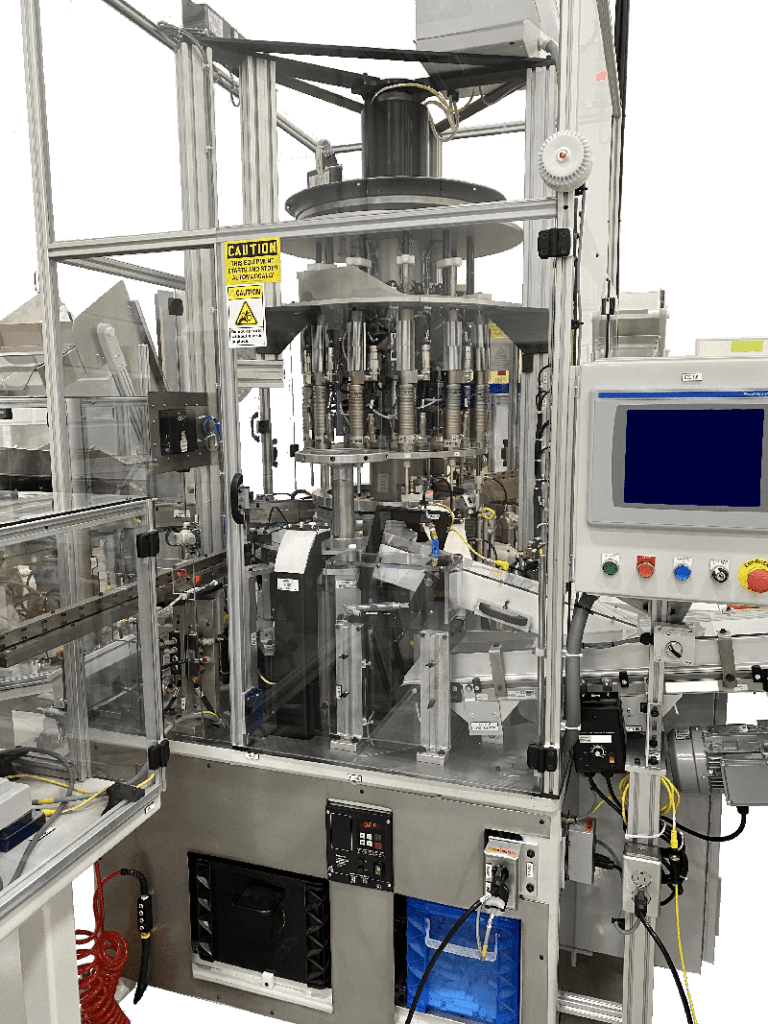

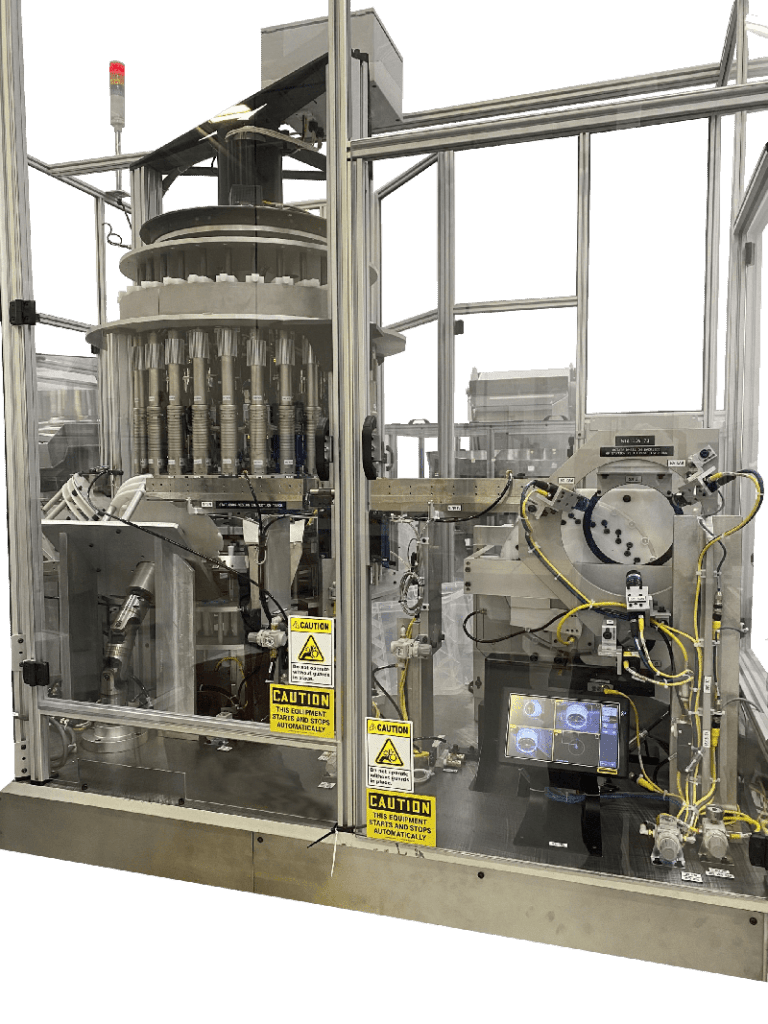

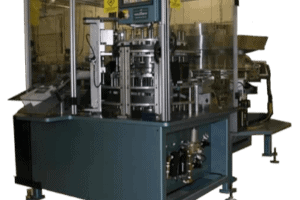

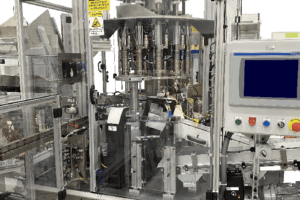

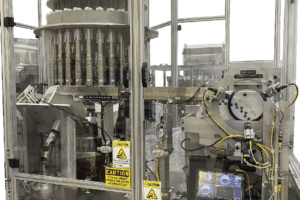

- Cap closing. Our self-contained continuous motion cap closing machinery is effective on caps of various sizes, diameters, and types, and users can easily integrate them into their production line for up to 550 ppm.

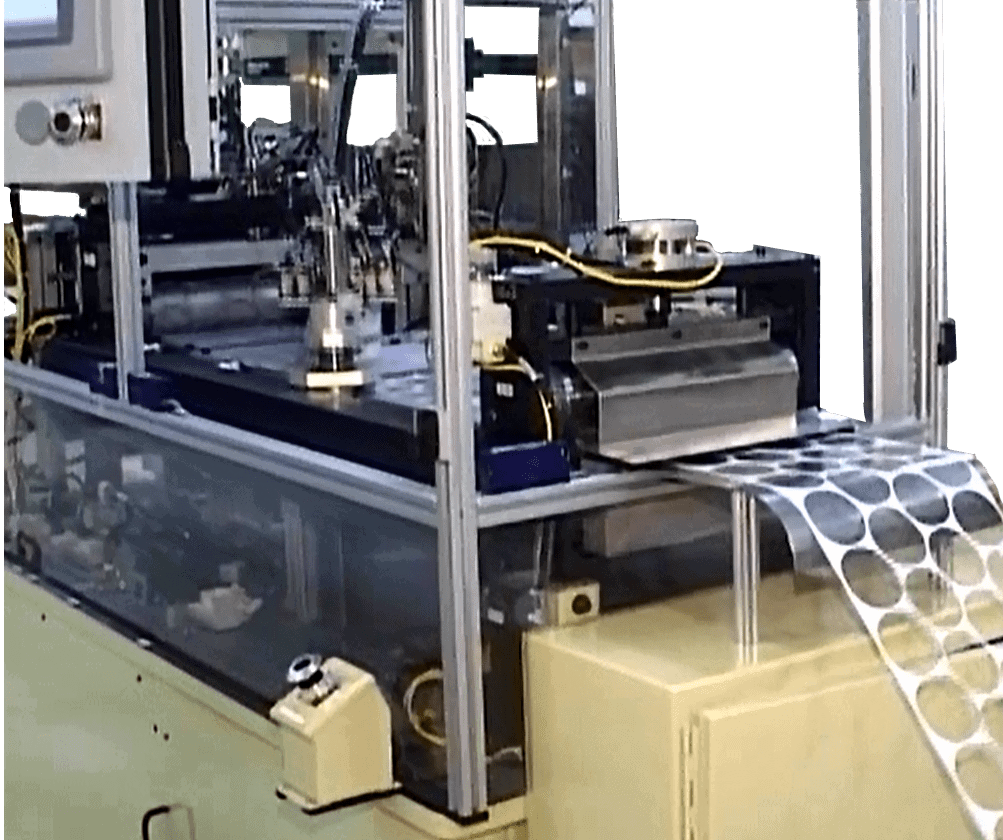

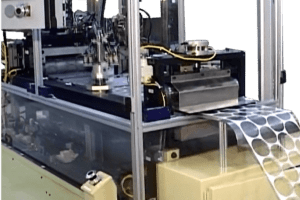

- Cap lining. Our punch and die, roller or rotary die lining machines utilize custom dies and rolls of liner material to precisely cut flat, round shapes that our CAM-actuated slides can transfer onto closures at a rate of up to 1,200 ppm.

- Cap assembly. Central Machines offers continuous motion assembly machinery for multi-piece assembly at a maximum of 1,300 ppm.

- Slitting closures. For use with plastic closures, automated slitting machinery generates tamper-evident (TE) breakaway rings.

- Band folding closures. Often part of the same machinery that carries out slitting, band folding equipment folds TE bands for plastic beverage caps.

- Leak testing. For leak test equipment, our team can custom-manufacture automated assembly machinery with leak-testing functionality to customers’ specific requirements.

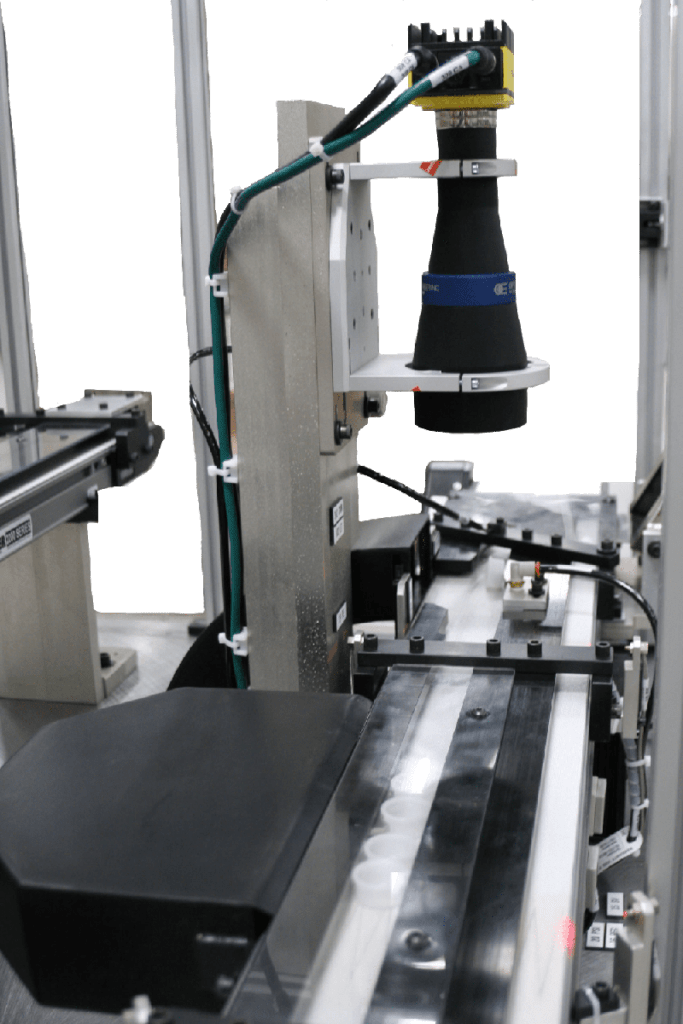

- Vision inspecting. As a customized option, Central Machines can manufacture vision inspection systems or specific controls to enable automated quality assurance. We also offer Cognex, Keyence, and Omron options.

Benefits of Automated Assembly Equipment

Food industry automation has become an essential aspect of the sector, transforming food production by improving product quality and reliability. Advantages of automated machines for the food industry include:

- Increased efficiency and output. Automated technology operates faster and longer than the human workforce, allowing businesses to boost productivity and work around the clock. Also, companies can easily integrate new equipment into the manufacturing process for flexible scalability that streamlines operations.

- Quality control. At best, poor quality can slow production, generate extra work, and reduce consumer confidence in a brand. At worst, quality flaws in this industry may impact product safety and consumer health. Automated systems remove the risk of human error and carry out processes repeatably and with reliable precision.

- Real-time traceability. Technological advancements have enabled automated machinery to track and monitor products from raw materials through delivery. Users can review the supply chain to get real-time information or assess quality control with minimal human input.

- Worker safety. Automation removes the need for employees to undertake repetitive, strenuous, or risky activities, increasing worker satisfaction, decreasing injuries, and freeing staff up for more critical corporate responsibilities.

- Waste management. Automation minimizes defects, which cuts down on the need for additional raw materials and reworking. Also, automated processes have a high degree of precision, generating less scrap. Reducing oversupply in inventory positively impacts spoilage risks, as well.

- Decreased costs. Automation’s reductions in manual labor, human error, and material waste coupled with increased production output and precision accuracy enable significant financial benefits.

Standards and Compliances

The U.S. Food and Drug Administration (FDA) regulates everything from food, beverages, and pharmaceuticals to healthcare devices, electronics, and consumer products. The organization also covers deceptive product marketing. Their ultimate goal is to ensure consumables and products are safe for distribution to protect public health. Central Machines recognizes the importance of FDA regulations in the food and beverage industry, and we employ non-toxic and non-reactive materials in our machines that are both durable and easy to clean.

Automated Assembly Equipment From Central Machines

Central Machines provides some of the most innovative automation equipment for the food processing industry. Our skilled team utilizes state-of-the-art CAD, CAM, wire EDM equipment, and mechanical- and servo-driven motions to fabricate reliable, long-lasting components. We offer comprehensive in-house design, assembly, machining, wiring, programming, and testing to ensure end-product accountability and complete construction under one roof, as well as on-site installation, training, servicing, and retooling.

To learn more about our customized assembly equipment for the food and beverage industry, contact us today or request a quote to get started.

Specifications

| Applications | Cap Closing Cap Lining Cap Assembly Packaging Band Folding Closures Slitting Closures |

| Types of Machines Available | Continuous motion cap closing machines Continuous motion multiple piece assembly machine Custom Designed Machines Rotary die cap liner machines |

| Machine Production Rate | 20 to 1300 ppm or more |

| Standards Met | FDA Approved Materials |

| Safety Guarding Options | Electrically interlocked guarding Guarding for pinch points and rotating sections Light Curtains Perimeter guarding with clear polycarbonate panels Safety Relays |

| Feeder Type | Centrifugal Feeders In-Line Tracks Vibratory Feeders |

| Vision Systems | Cognex Keyence Omron Or Customer Specified |

| Testing Process | Leak Testing |