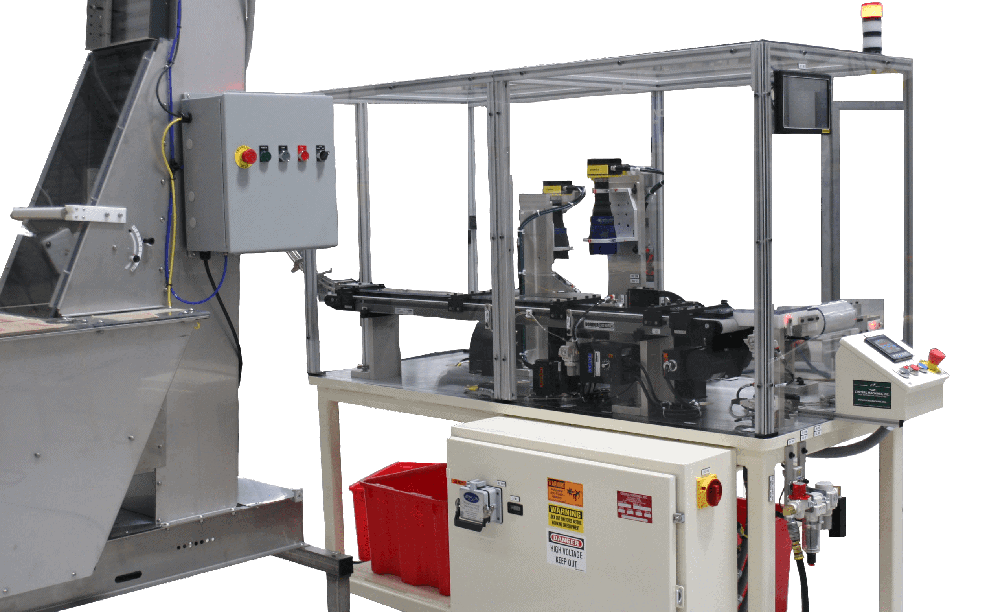

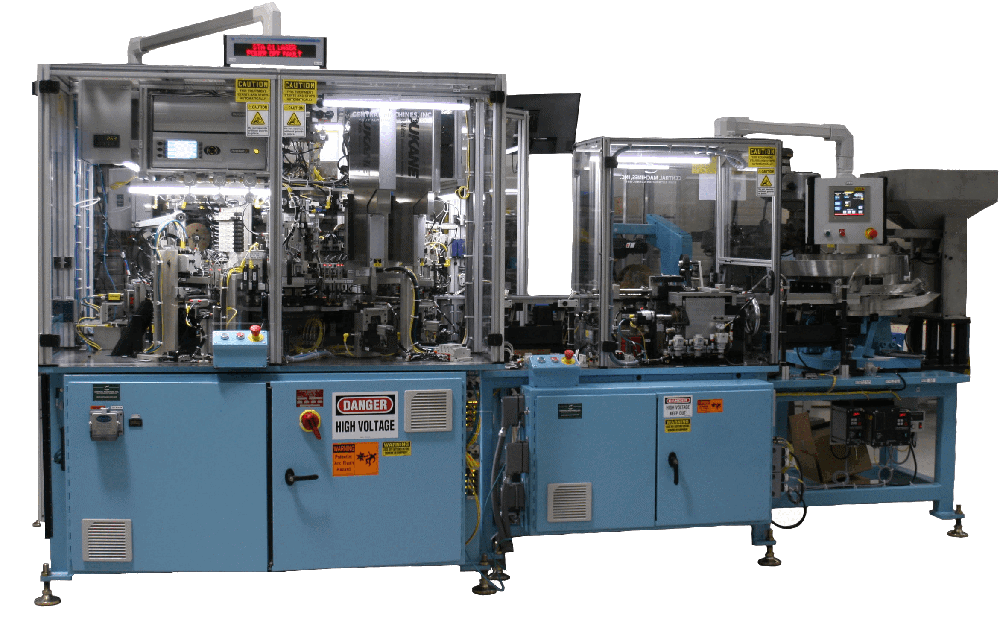

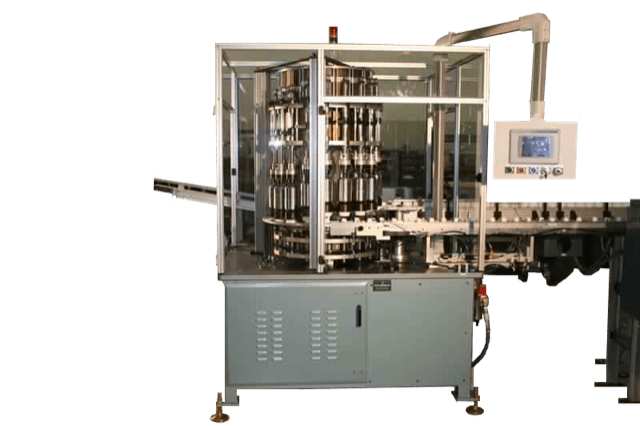

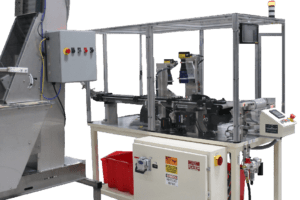

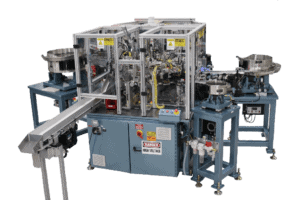

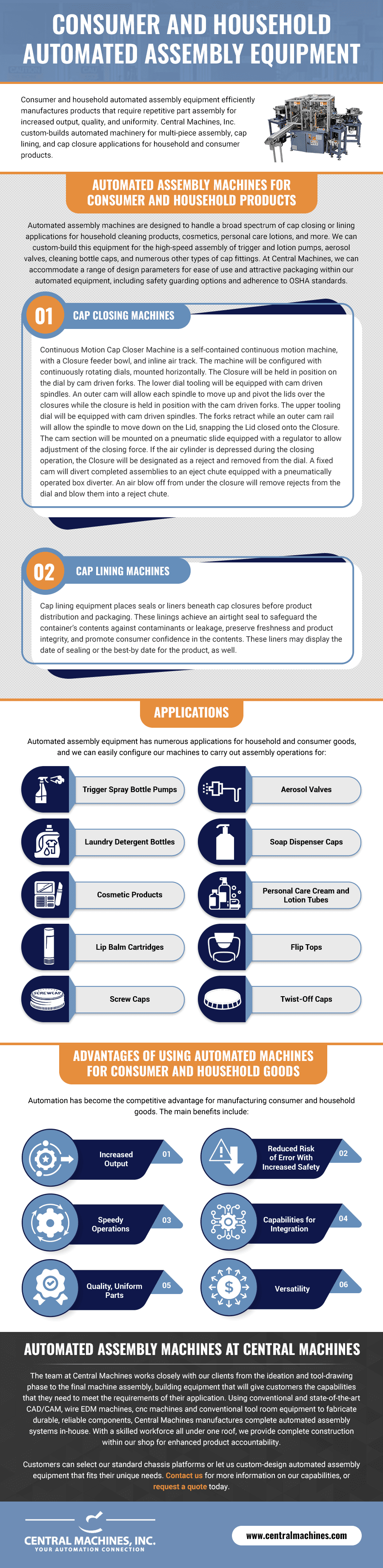

Consumer and household automated assembly equipment efficiently manufactures products that require repetitive part assembly for increased output, quality, and uniformity. Central Machines, Inc. custom-builds automated machinery for multi-piece assembly, cap lining, and cap closure applications for household and consumer products.

Automated Assembly Machines for Consumer and Household Products

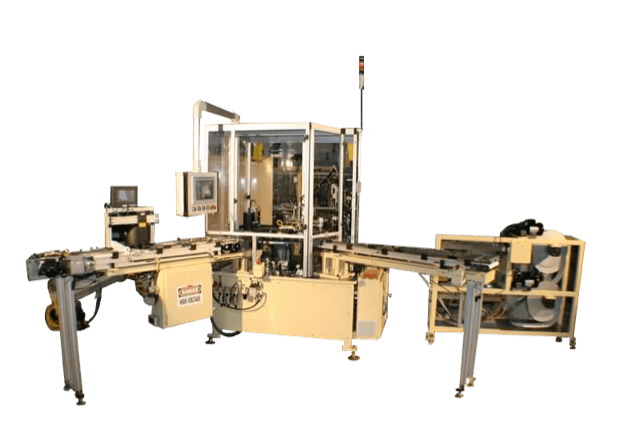

Automated assembly machines are designed to handle a broad spectrum of cap closing or lining applications for household cleaning products, cosmetics, personal care lotions, and more. We can custom-build this equipment for the high-speed assembly of trigger and lotion pumps, aerosol valves, cleaning bottle caps, and numerous other types of cap fittings. At Central Machines, we can accommodate a range of design parameters for ease of use and attractive packaging within our automated equipment, including safety guarding options and adherence to OSHA standards.

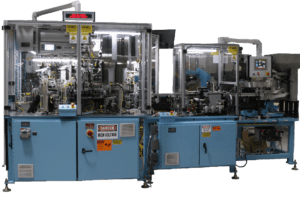

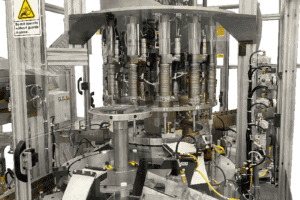

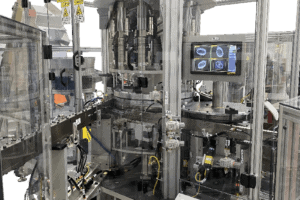

Cap Closing Machines

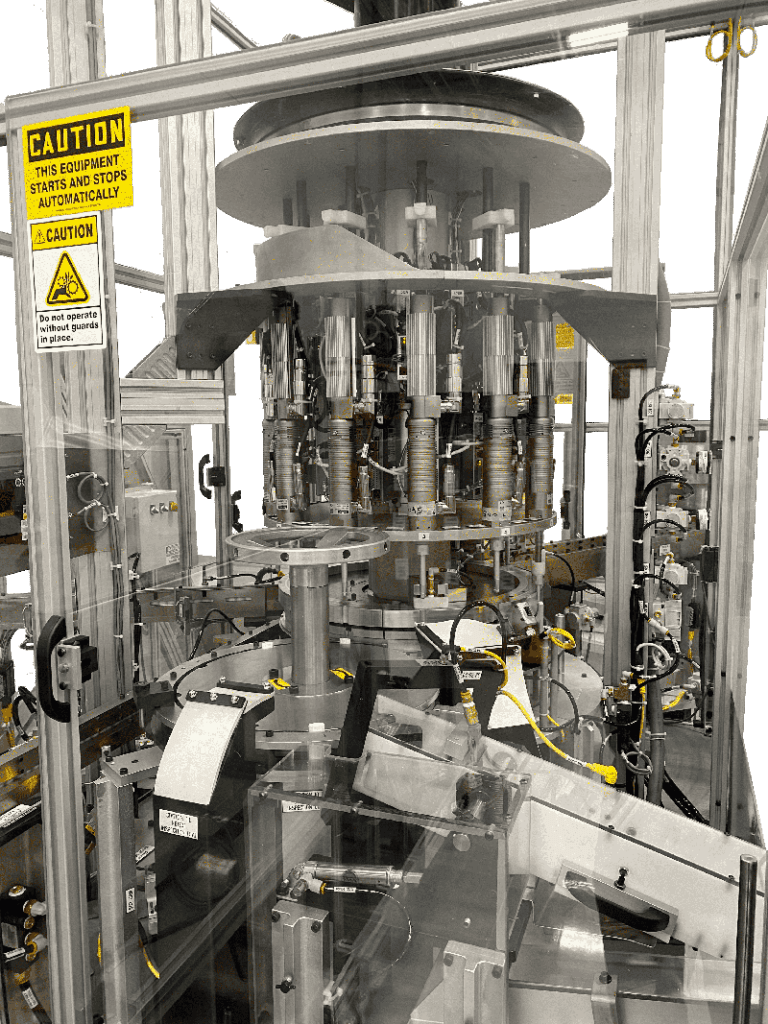

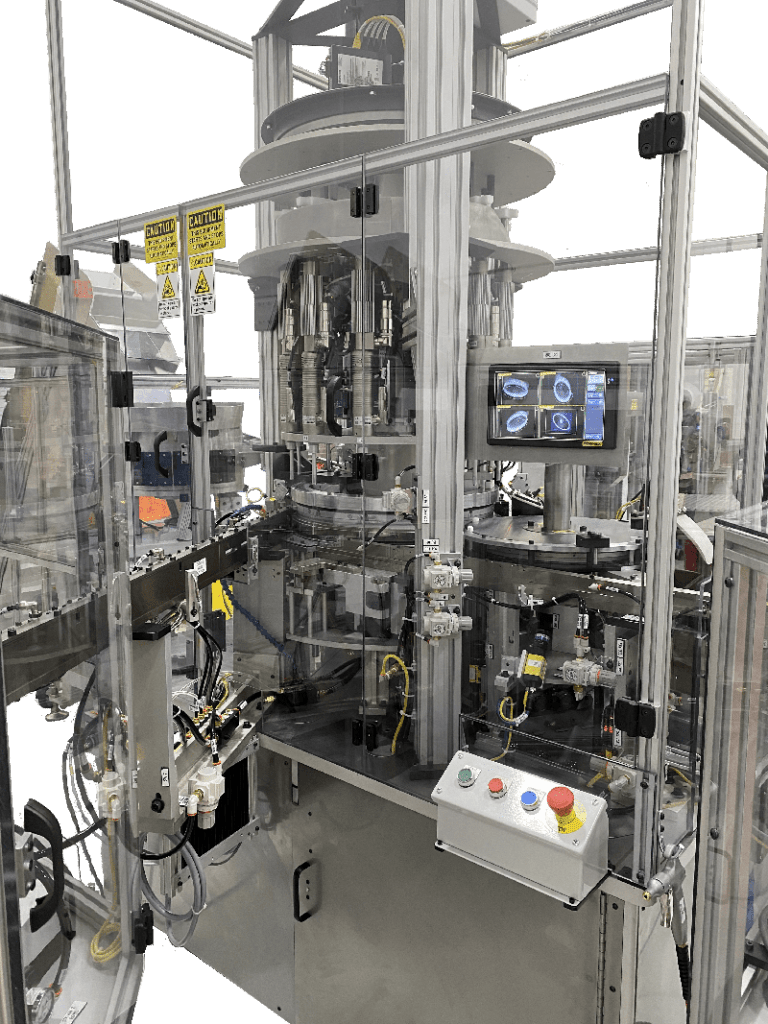

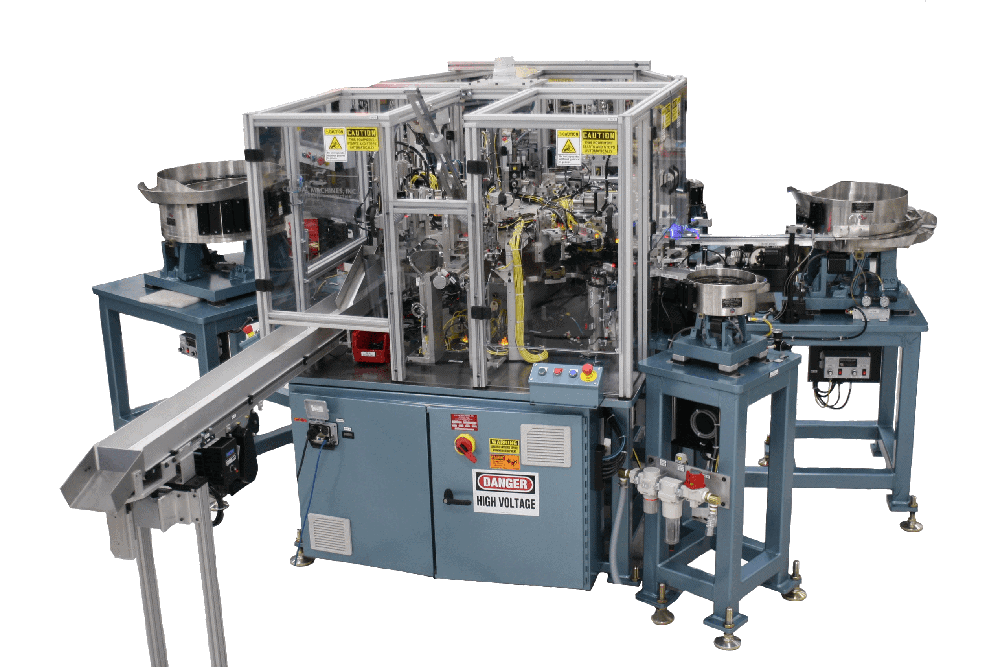

Continuous Motion Cap Closer Machine is a self-contained continuous motion machine, with a Closure feeder bowl, and inline air track. The machine will be configured with continuously rotating dials, mounted horizontally. The Closure will be held in position on the dial by cam driven forks. The lower dial tooling will be equipped with cam driven spindles. An outer cam will allow each spindle to move up and pivot the lids over the closures while the closure is held in position with the cam driven forks. The upper tooling dial will be equipped with cam driven spindles. The forks retract while an outer cam rail will allow the spindle to move down on the Lid, snapping the Lid closed onto the Closure. The cam section will be mounted on a pneumatic slide equipped with a regulator to allow adjustment of the closing force. If the air cylinder is depressed during the closing operation, the Closure will be designated as a reject and removed from the dial. A fixed cam will divert completed assemblies to an eject chute equipped with a pneumatically operated box diverter. An air blow off from under the closure will remove rejects from the dial and blow them into a reject chute.

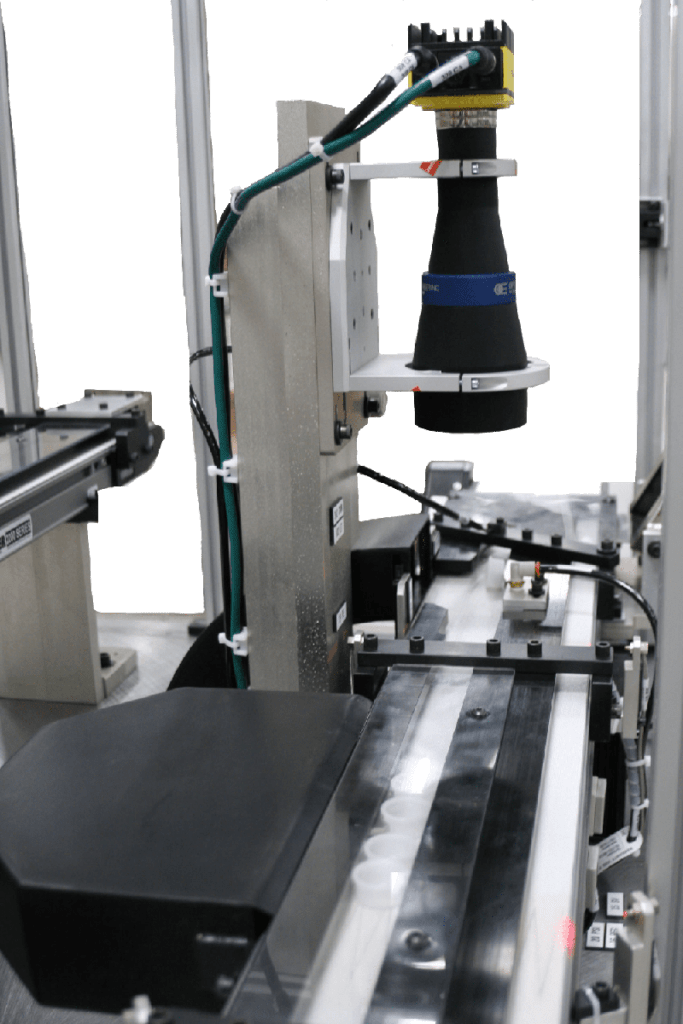

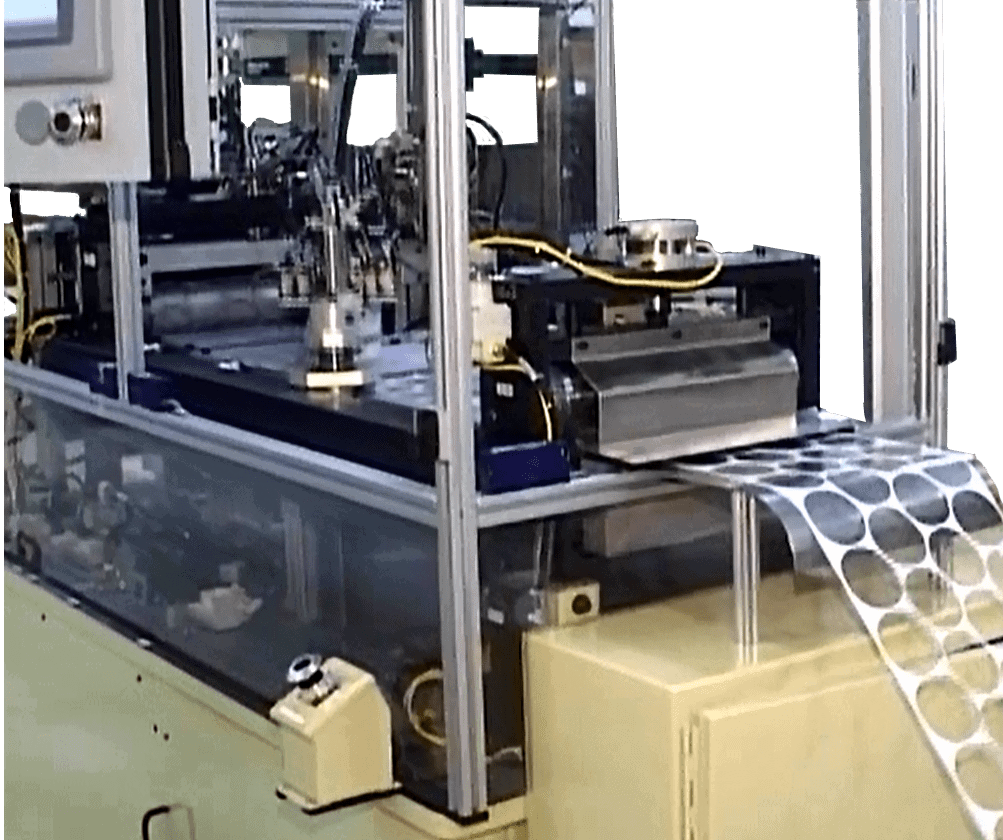

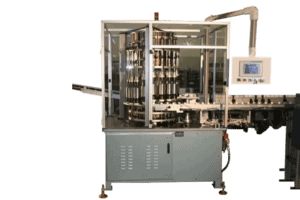

Cap Lining Machines

Cap lining equipment places seals or liners beneath cap closures before product distribution and packaging. These linings achieve an airtight seal to safeguard the container’s contents against contaminants or leakage, preserve freshness and product integrity, and promote consumer confidence in the contents. These liners may display the date of sealing or the best-by date for the product, as well.

Applications

Automated assembly equipment has numerous applications for household and consumer goods, and we can easily configure our machines to carry out assembly operations for:

- Trigger spray bottle pumps

- Aerosol valves

- Laundry detergent bottles

- Soap dispenser caps

- Cosmetic products

- Personal care cream and lotion tubes

- Lip balm cartridges

- Flip tops

- Screw caps

- Twist-off caps

Automated assembly machinery from Central Machines is equipped with automated identification and rejection capabilities for defective products to ensure a high level of product quality.

Advantages of Using Automated Machines for Consumer and Household Goods

Automation has become the competitive advantage for manufacturing consumer and household goods. The main benefits include:

Increased Output

Automated assembly equipment has the ability to work at a constant speed without much human interaction. Automated machinery can operate unattended and work around the clock without needing a break. This creates a valuable opportunity for manufacturers to generate large production volumes and increase profitability.

Reduced Risk of Error With Increased Safety

A machine that performs repetitive, automated tasks is less likely to make mistakes than a human employee, enabling manufacturers to produce highly repeatable, consistent components. This also contributes to a safer working environment because automated machines remove workers from dangerous tasks and situations.

Speedy Operations

With high repeatability and less human error, automated assembly equipment speeds up production times. Additionally, manufacturers can introduce new products or components into the process with little or no disruption to existing processes.

Capabilities for Integration

Manufacturers can incorporate a complete automated assembly system into their production facilities quickly and easily. With capacities anywhere from 20 to 1,200 components per minute, our equipment is easy to integrate into virtually any preexisting dispensing operation for a variety of similar household goods. Central Machines provides turnkey service from engineering design and machine shop fabrication to assembly, wiring, programming, installation, training, and maintenance.

Quality, Uniform Parts

Automated systems are capable of manufacturing products with less variability than human employees. The result is greater control in the manufacturing process, consistent product quality, and cost savings on scrapped or reworked parts.

Versatility

Automated assembly equipment offers production process flexibility with reduced changeover time. Operators can easily redeploy the machinery for new applications and switch between a wide range of products or processes without the need to completely rebuild production lines.

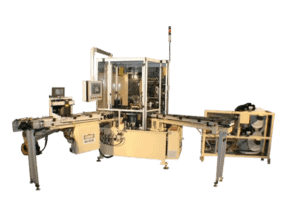

Automated Assembly Machines at Central Machines

The team at Central Machines works closely with our clients from the ideation and tool-drawing phase to the final machine assembly, building equipment that will give customers the capabilities that they need to meet the requirements of their application. Using conventional and state-of-the-art CAD/CAM, wire EDM machines, cnc machines and conventional tool room equipment to fabricate durable, reliable components, Central Machines manufactures complete automated assembly systems in-house. With a skilled workforce all under one roof, we provide complete construction within our shop for enhanced product accountability.

Customers can select our standard chassis platforms or let us custom-design automated assembly equipment that fits their unique needs. Contact us for more information on our capabilities, or request a quote today.

Specifications

| Applications | Aerosol Valve Assembly Band Folding Cap Closing Cap Lining Detergent Closure Assembly Multiple Piece Assembly Slitting Closures Trigger Pump Assembly |

| Types of Machines Available | Continuous Motion Multiple Piece Assembly Machines Continuous Motion Cap Closing Machines Roller Die Liner Machines Pick and Place Machines Carousel Machines Indexing Dial Multiple Piece Assembly Machines Walking Beam Machines Palletized Machines Custom Designed Machines |

| Machine Production Rate | 20 to 1300 parts per minute |

| Safety Guarding Options | Electrically interlocked guarding Guarding for pinch points and rotating sections Light Curtains Perimeter guarding with clear polycarbonate panels Safety Relays |

| Standards Met | OSHA Standards |