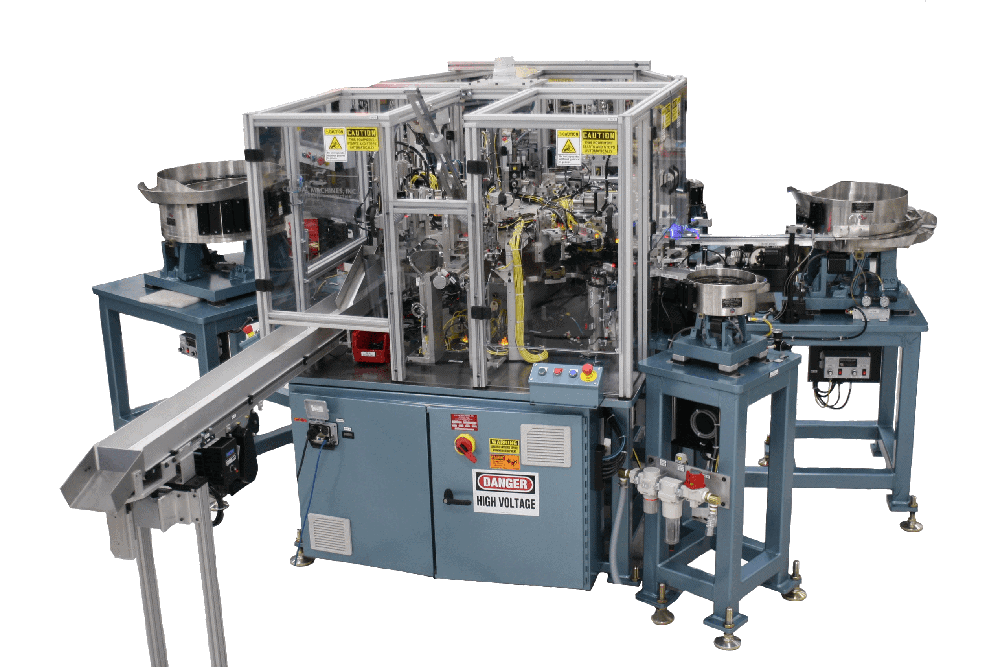

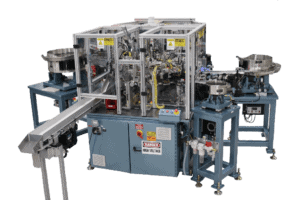

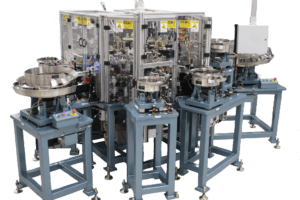

Indexing dial multiple-piece assembly machines provide dwell time which allows for multiple, complex operations to be preformed accurately and typically at a lower cost than continuous motion machines. Central Machines is experienced with creating indexing machines that can perform operations such as assembly, testing, inspection, heat staking, ultra-sonic welding and flash trimming during this important dwell time. Operations such as electrical connector and component assembly, as well as other assemblies from ink jets to baby bottles can all be performed on our index machines.

Another advantage of these machines is their functional flexibility. They can assemble and perform operations on parts that would be too large for continuous motion machines. Once our design team determines your production needs, we will recommend the best solution to fit your functional and financial criteria. Because each customer is different, we offer a long list of options from inline vibratory or centrifugal feeders to defective part sensors to multiple machine integration.

From each and every machine our customers can expect longevity and reliability due to our use of mechanical and servo driven motions. Our skilled work force is all under one roof, allowing for the complete construction, and product accountability, within our shop. We use both conventional and state-of-the-art CAD/CAM and wire EDM machines to fabricate the components.

Our machines are user friendly and programmable. A color display touch screen panel is the primary user interface. Using the touch screen, the equipment can be programmed to run different jobs. Operators need only to enter a part number into the touch screen and the machine will access its local data base to start producing the part.

We performance-test, debug, and install all the equipment that we build. Our skilled personnel provide phone support, on-site maintenance and servicing support. Lastly, we provide training on equipment installation and usage.

- Capabilities

Machine Shop Capabilities Buffing

CNC Machining

Drilling

Milling

Sawing

Stamping

Welding

Wire EDM MachiningCustom Services 24/7 Service

Complete Machine Programing

Custom Build Manufacturing

Functional Testing

Innovative Machine Design

Installation At Your Location

Retooling and Upgrades of our machines and our competitor’s machines

Stand Alone Machines

Training Your Staff

Turnkey Systems

Wiring and AssemblyFabrication Materials Used For

Building Chassis and ToolingAluminum: 6061, 2024

Cold rolled steel bar and plate stock; 1008,1018, 1020

Heat Treatment of Materials Available if Necessary

Sheet Metal (8-14 gauge)

Stainless Steel : All grades

Tool Steel: CPM, 10V, D2, A2, M2Tolerances Operating Placement: +/- .002

Tooling tolerance: +/- .001Sensor Capability Verify product has no defects

Verify Product was assembled correctly

Verify Product was loaded into the dials

Verify that products with defects are removedCore Competencies Cap Closing Machines w/ max. 550 ppm

Cap Lining Machines w/ max. 1200 ppm

Continuous Motion Assembly Machines w/ max. 1300ppm

High Speed Indexing Assembly Dial w/ Typical min. 25 ppm to max. 150 ppm.

Walking beam-type transfer systems - Design Options

Feed Systems Vibratory feeders

Centrifugal feeders

Water fall feeders

Step feedersIn Feed Systems Power driven conveyors tracks

Regenerative blower tracks

Compressed air tracks

Vibratory inline tracksProduct Transfer to Assembly or Test Processes Direct feed

Cam / servo / pneumatic driven pick and place units

Servo / pneumatic driven gantries

Cam / servo / pneumatic driven shuttlesProduct Placement Detection See through fiber optic sensors

Convergent beam sensors

Laser sensors

Probe tooling with sensorsProduct Assembly Types Snap together

Interference fit

Adhesive

Dispensing

Ultra sonic welding

Heat staking

Welding

Spin welding

Induction welding

Conduction welding

Screwing

RivetingProduct Assembly Testing Vision system inspections

Probe tooling with sensors

Laser sensors

Leak testing (pressure or vacuum)

Spark testing

Hi- Pot electrical high voltage testing

Go / No go tooling gages

LVDT force testing

Automatic ejecting of product to sampling binsProduct Identification Laser engraving

Ink jet printing

Labeling

Pad printing

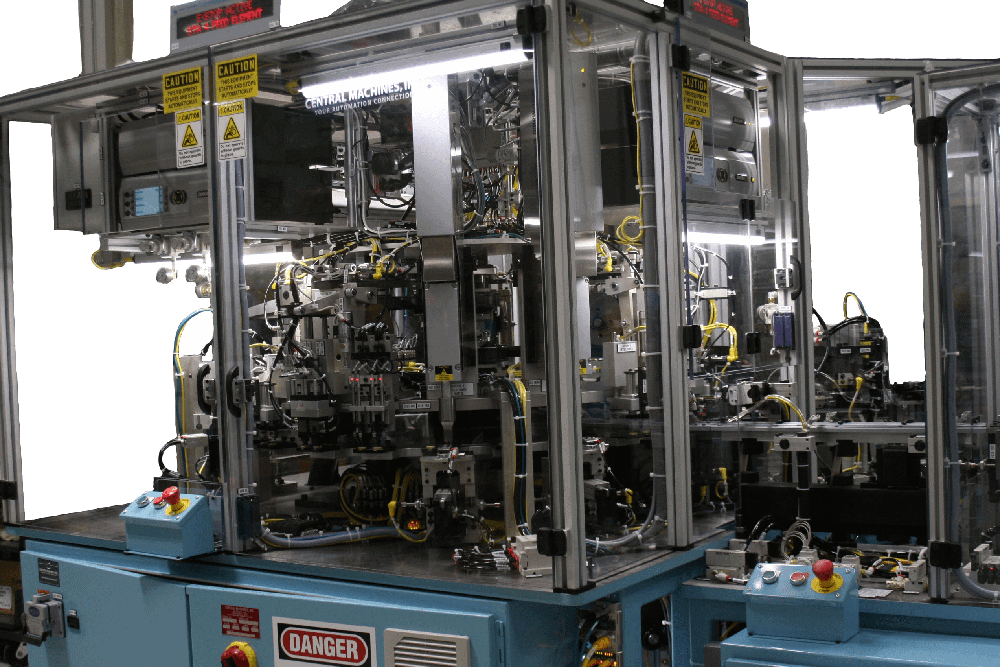

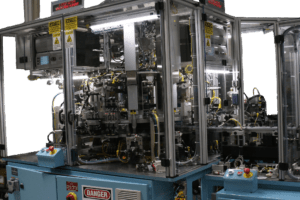

Pin stamping - General Machine DescriptionThe Indexing Dial Multiple Piece Assembly Machine is based on Central Machines standard dial-indexing platform with cam driven pick & place units mounted in board of the assembly dial to provide good accessability to the individual stations.

The machines include the following standard features:

- A Precision Indexer with precision stops will drive the tooling dial plate.

- Piece part fixtures mounted to the indexing dial plate will transport product between stations.

- Feeder bowls to orient product.

- In-feed tracks to transfer the product to the pick and place escapements.

- Precision cam driven pick and place devices that transfer product from the escapements to the fixture nest.

- Off load conveyor to transfer assemblies to a two position box diverter.

- Fixture tracking system will monitor good and bad parts thru the system.

- Touch screen operator interface with message display.

- Mechanical and Electrical operating manuals.

Each station is mounted on identical station plates for added flexibility, and is constructed with tooling mounted to a ground steel top plate supported by a fabricated steel base. Mechanical, pneumatic and electrical equipment are group mounted on the base. Electrical controls are mounted in NEMA 12 style enclosures and all tooling will be hardened and ground. Machine components can be anodized, plated, or painted as necessary. Pinch points and rotating sections will be guarded to prevent operator injury. Perimeter guarding is electrically interlocked and fabricated with clear polycarbonate panels and extruded aluminum.

- Inspection & Testing

Functional Testing and Inspection 24 hour non-stop dry run test

Electrical test on connectors: Hypot test

Multi stage load test

Standard ChecklistProject Completion Internal Check List Control Panel Wiring and function

Correct Preparation for Shipment

Electrical Engineering Documentation

Guarding and Saftey

Mechnical Assembly

Mechnical Engineering Documentation

Pneumatic Wiring

Proper Lubrication - Engineering & Services

CAD Software Used Autodesk Inventor

Automation simulation using CAD designing softwareEngineering Concepting

Process DevelopmentCustom Services 24/7 Service

Complete Machine Programing

Custom Build Manufacturing

Functional Testing

Innovative Machine Design

Installation At Your Location

Retooling and Upgrades of our machines and our competitor’s machines

Stand Alone Machines

Training Your Staff

Turnkey Systems

Wiring and Assembly - Additional Options

Pre Feeders Elevator hoppers

Vibratory hoppers

Live bottom hoppersPack Out Systems Carton handling systems with powered or roller conveyors

Stacking

Robotic packaging

Two position carton divertersOperator Interface Touch screen with machine diagnostics and data acquisition

Push button

Message display units

Placard displays