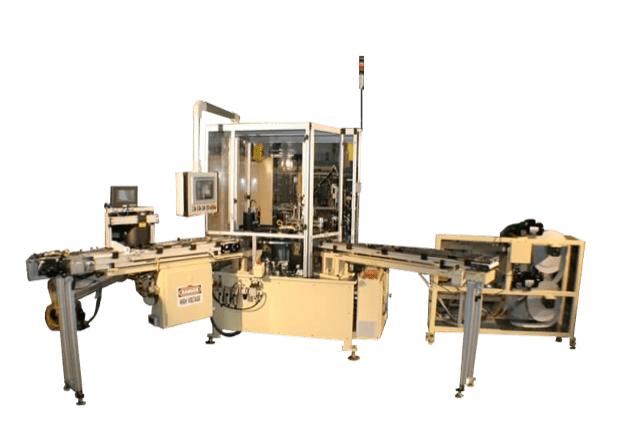

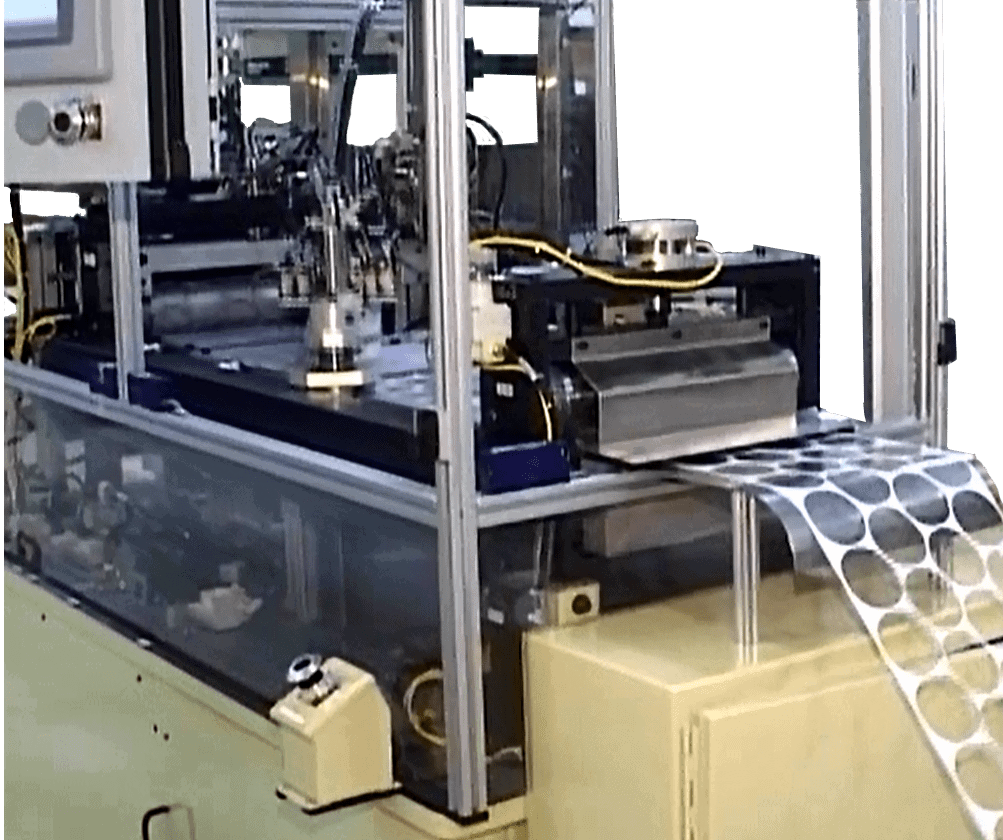

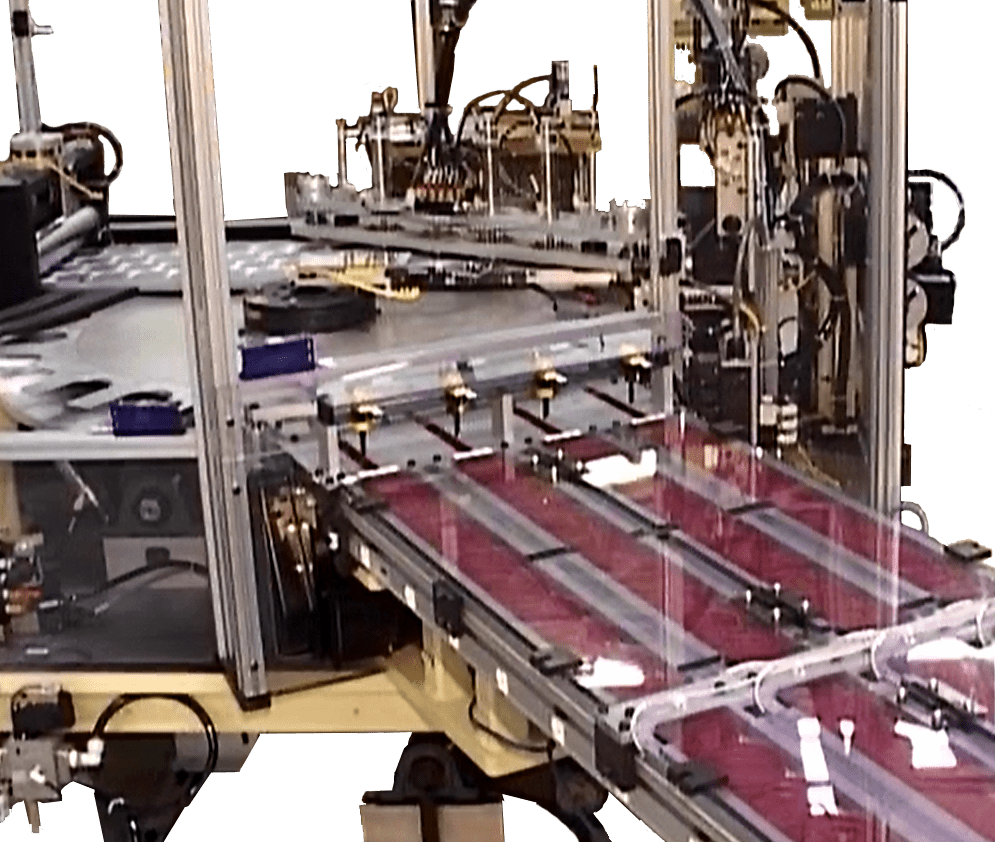

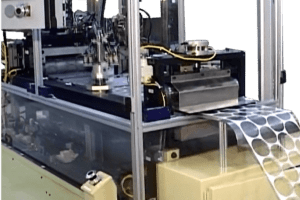

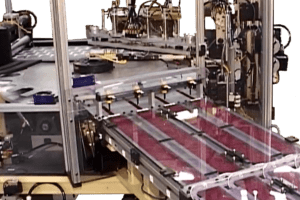

We provide custom-built roller die liner machines for cap lining with all types of closures. Liner materials, fed with reels into the machines, are precision cut to specific patterns using special designed roller dies. Our roller dies can cut flat, round shapes from rolls of cap liner materials. CAM actuated slides with tooling heads transfer the shaped liner material into the closures.

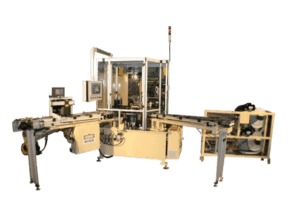

Die liner machines with multiple insertion tooling can be built to fill liner material in up to 1200 closures per minute. Machines are available with both vibratory, waterfall or centrifugal feeders, and in-line tracks for continuous flow of parts in the production line. If required, die-reelers, motorized stock feeders, automatic changing and loading of liner material, scrap re-reelers, or choppers can also be added. Our machines can be integrated with secondary closure processing equipment such as closing or multiple piece closure assembly machines.

Tooled for 1, 2, 3, 4, or 6-up configurations, the rotary die we use cut with ease and only require reduced maintenance. Station tooling mounted to steel plates can be hardened and grounded. Pinch points as well as rotating areas are guarded according to the best practice principles of machine design and OSHA standards. Perimeter guarding can be fabricated with clear polycarbonate panels as well.

From each and every machine our customers can expect longevity and reliability due to our use of mechanical and servo driven motions. Our skilled work force is all under one roof, allowing for the complete construction, and product accountability, within our shop. We use both conventional and state-of-the-art CAD/CAM and wire EDM machines to fabricate the components.

- Specifications

Closure Type Round Flat Closure Form of Product Liner Material – Supplied on reels

Round Flat Closure – Supplied in bulkFeeder Type Centrifugal Feeders

In-Line Tracks

Vibratory FeedersProduction Rate Ranges Up to 1200 parts per minute Machine Platform Cap Liner Machine with Roller Die Configuration

Conventional Punch & Die ConfigurationsDie Configuration Precision Rotary Die (1, 2, 3, 4 or 6-Up) Machine Features De-reeler

Motorized Stock Feeder

Scrap re-reeler

Cam actuated slide with tooling head

Operator Interface

Automatic Liner

Material Changes

Other Options Available

ScrapTooling Hardened and Ground

Station tooling mounted to ground steel top plate, supported by fabricated steel base

Tolerance: +/- 0.001”Safety Guarding Options Electrically interlocked guarding

Guarding for pinch points and rotating sections

Perimeter guarding with clear polycarbonate panels

Safety Relays - Design Options

Feed Systems Vibratory feeders

Centrifugal feeders

Water fall feeders

Step feeders

Accumulation dialsIn Feed Systems Power driven conveyors tracks

Regenerative blower tracks

Compressed air tracks

Vibratory inline tracks - Inspection & Testing

Testing Process 24 hour non-stop dry run test

Final Debugging

Hypot test for electrical test on connectors

Multi-stage load test

Standard Checklist - More Information

CAD Software Used Autodesk Inventor Other Services Available Automation simulation through CAD designing software

Retooling of standard machines and other manufacturer’s machinesIndustries Served Consumer/Household

Electrical

Electronics

Food and Beverage

Medical/Pharmaceutical - Additional Options

Product Placement Detection See through fiber optic sensors

Convergent beam sensors

Laser sensors

Probe tooling with sensorsPre Feeders Elevator hoppers

Vibratory hoppers

Live bottom hoppersLiner Material Handling De-reeler system holding two reels of liner material

Automatic loading and changing of liner material into machine

Liner scrap chopper

Scrap liner re-winderDie Removal Systems Electric wench with slide Product Assembly Testing Vision system inspections

Automatic ejecting of product to sampling binsPack Out Systems Carton handling systems with powered or roller conveyors

Stacking

Robotic packaging

Two position carton divertersOperator Interface Touch screen with machine diagnostics and data acquisition

Push button

Message display units

Placard displays